50

Model FL4000H

NOTE:

If the address is not in range an Illegal Data Value (03) is returned. By grounding the

RESET input during the first 1 second of the power up cycle, the FL4000H Address will

default to 1. The address will be set to a default of 1 when the red and green LED’s

flash alternately after approximately 1 second, at which time the RESET input can be

released from ground.

4.10.10

COM1 Baud Rate (0x000B)

A read command returns the current baud rate for COM1 channel. A write command changes

the baud rate to the requested values. Valid settings are shown in Table 33.

Factory default is

19,200 baud.

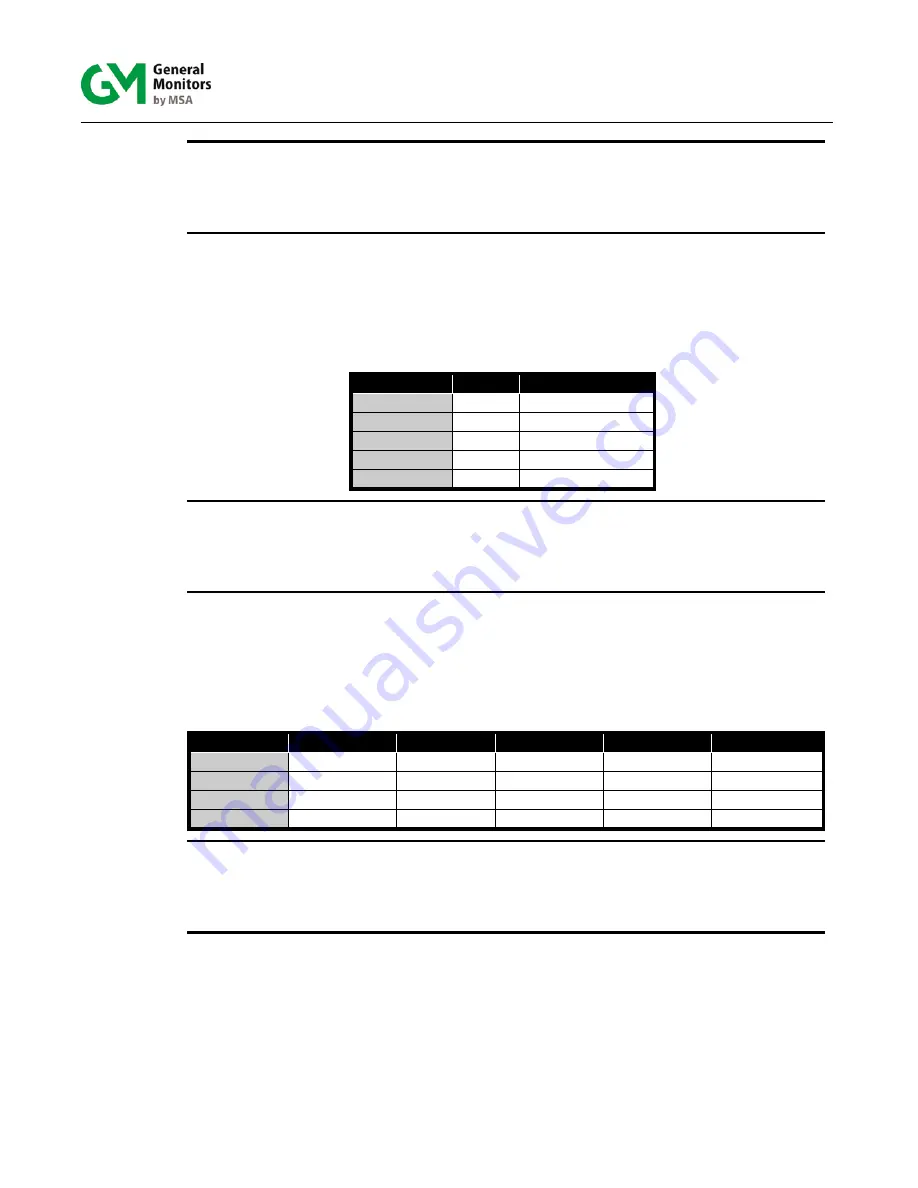

Table 33: Com1 Baud Rate

Baud Rate

Value

Access

2,400

0

Read / Write

4,800

1

Read / Write

9,600

2

Read / Write

19,200

3

Read / Write

38,400

4

Read / Write

NOTE:

If the baud rate is not in range, an Illegal Data Value (03) is returned. By grounding the

RESET input during the first 1 second of the power up cycle, the FL4000H Baud Rate

will default to 19.2K. The baud rate will be set to a default of 19.2K when the red and

green LED’s flash alternately after approximately 1 second, at which time the RESET

input can be released from ground.

4.10.11

COM1 Data Format (0x000C)

A read command returns the current data format for COM1 channel. Write command changes

the data format to the requested values. Valid settings are shown in Table 34. Default format is

8-N-1.

Table 34: Selectable Data Formats

Format

Parity

Stop

Data Bits

Value

Access

8-N-1

None

1

8

0

Read / Write

8-E-1

Even

1

8

1

Read / Write

8-O-1

Odd

1

8

2

Read / Write

8-N-2

None

2

8

3

Read / Write

NOTE:

If the data format is not in range, an Illegal Data Value (03) is returned. By grounding

the RESET input during the first 1 second of the power up cycle, the FL4000H Data

Format will default to 8-N-1. The Data Format will be set to a default of 8-N-1 when the

red and green LED’s flash alternately after approximately 1 second, at which time the

RESET input can be released from ground.

4.10.12 COPM

Counts

Sensor 1 (0x000D)

A read indicates the number of COPM Faults that have occurred for sensor 1 in the FL4000H.

Please refer to Section 2.4.2 for more information on COPM and Section 6.0 for

troubleshooting tips.

Summary of Contents for FL4000H

Page 2: ...ii Model FL4000H This page intentionally left blank ...

Page 8: ...viii Model FL4000H Figure 2 Mounting Instruction Figure 3 Wall Mounting Assembly ...

Page 28: ...28 Model FL4000H Figure 16 Detector Mounting and Installation ...

Page 61: ...61 Model FL4000H 6 2 Final Assembly Figure 26 FL4000H Cross Section View ...