Model IR400

15

3.4 Applying Power

Before applying power to the system for the first time, all wiring connections should be checked

for correctness. Upon initial power-up or after a fault condition has been corrected, the unit will

enter a start-up mode for 2 minutes before normal operation. IR400 Ethylene start-up can take

up to 10 minutes. As a unit warms up, output may briefly be negative.

After power is applied, the IR400 should be allowed to stabilize for approximately 60 minutes

while the unit attains the proper operating temperature. After stabilization, it is recommended

that the IR400 be zeroed, per the procedure in Section 4.1 (step 1 only). A gas check should

then be performed to ensure that the unit is operating properly. Use the General Monitors gas

check kit (P/N 32548-x) to perform this check. If the unit does not respond properly, calibrate

per the procedure in Section 4.1.4 (steps 1-4).

•

When connecting the IR400 to a safety system, the +24 VDC (red) wire should be the last

wire connected and first wire disconnected when removing the unit to protect the system

from shorting.

•

If the analog (4-20 mA) output is not used, then the white signal wire must be connected to

ground to prevent a fault condition.

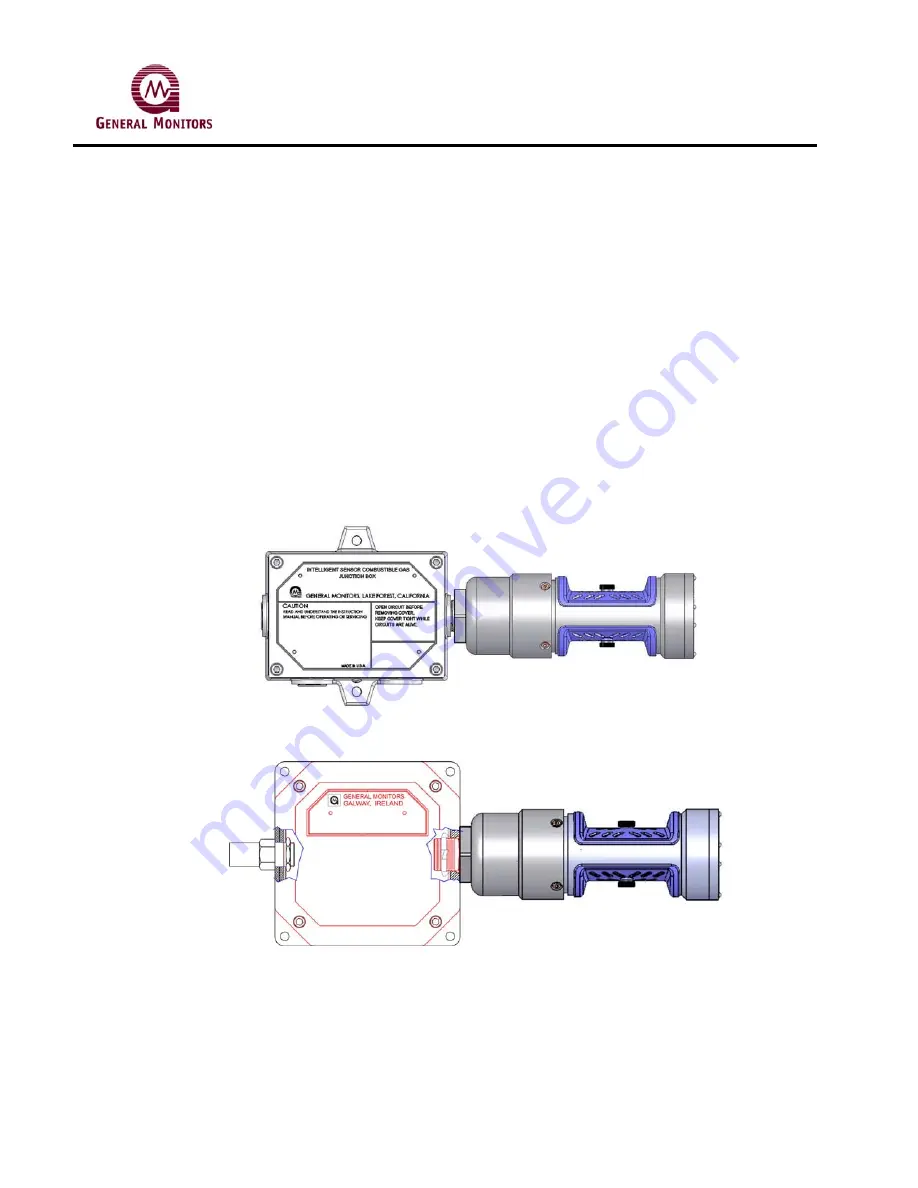

Figure 6a: IR400 with Junction Box

Figure 6b: IR400 with European Junction Box

Summary of Contents for IR400

Page 2: ......

Page 15: ...Model IR400 11 Figure 5b IR400 Mounting Dimensions with a European Box ...

Page 20: ...Model IR400 16 Figure 7 Wiring Diagram from IR400 to Control Equipment ...

Page 41: ...Model IR400 37 9 6 Engineering Documentation ...

Page 45: ...Model IR400 HART Field Device Specification for Point IR Gas Detector ...

Page 78: ...Model IR400 Infrared Point Detector for Hydrocarbon Gas Applications Modbus programming guide ...