Model IR400

20

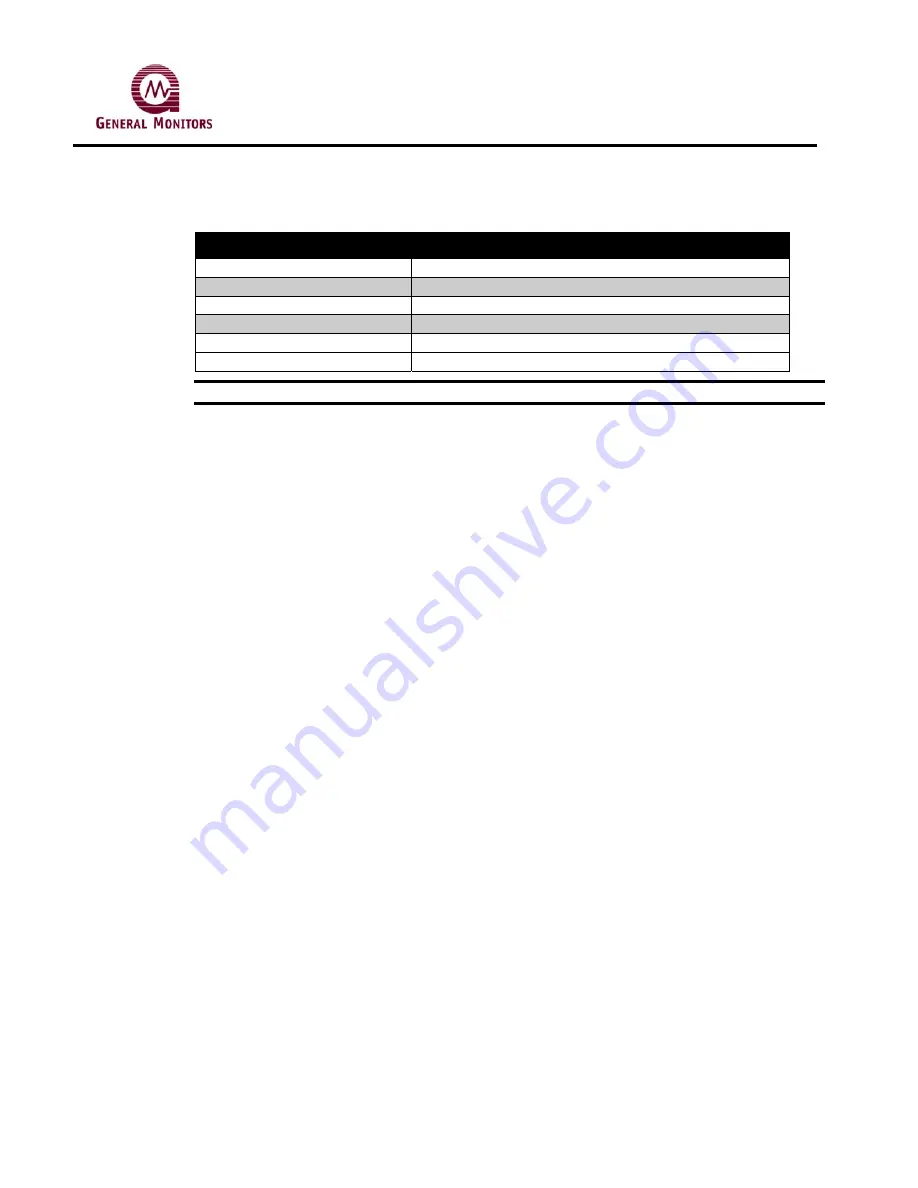

4.1.6 IR400 Zero Switch / LED flashing patterns

Flashing Pattern (ms)

Description

1000 on, 1000 off

Zero

950 on, 50 off

Zero complete, calibration pending

100 on, 400 off

Calibration, apply gas

500 on, 1000 off

Gas present, calibration in progress

980 on, 20 off

Calibration complete; remove gas

100 on, 100 off

Fault

•

NOTE:

This table is for Zero Switch / LED calibration input configurations only.

4.2 IR400 Stand-alone Operation and Configuration

The IR400 does not have built-in operation and configuration menus without an IR4000.

However, zeroing and calibration can be accomplished using the Zero (magnetic) Switch / LED

on the junction box that is directly attached to the IR400. You should ‘zero’ the Model IR400

detectors occasionally to eliminate any background gas fluctuations. Calibration is necessary if

gas check readings show the unit is reading inaccurately.

In addition, many operational functions are available using the Modbus/HART interface from a

control room device, as described in separate General Monitors’ manuals (available from our

website).

4.2.1 To Zero and Calibrate a Stand-alone IR400 Using a Magnetic Switch

This procedure describes how to use the IR400 junction box magnetic switch to zero and

calibrate the IR400. Once zeroing or calibration begins, the alarm and warning relays are

automatically kept disabled, and the analog signal is held at 1.5 mA. As you follow the

procedure steps, refer to the figure shown below for the LED indicator.

Summary of Contents for IR400

Page 2: ......

Page 15: ...Model IR400 11 Figure 5b IR400 Mounting Dimensions with a European Box ...

Page 20: ...Model IR400 16 Figure 7 Wiring Diagram from IR400 to Control Equipment ...

Page 41: ...Model IR400 37 9 6 Engineering Documentation ...

Page 45: ...Model IR400 HART Field Device Specification for Point IR Gas Detector ...

Page 78: ...Model IR400 Infrared Point Detector for Hydrocarbon Gas Applications Modbus programming guide ...