Model IR400

26

5.3 Cleaning and Lubricating the IR400 and IR4000 Units

5.3.1 Cleaning the IR400 and IR4000 Units

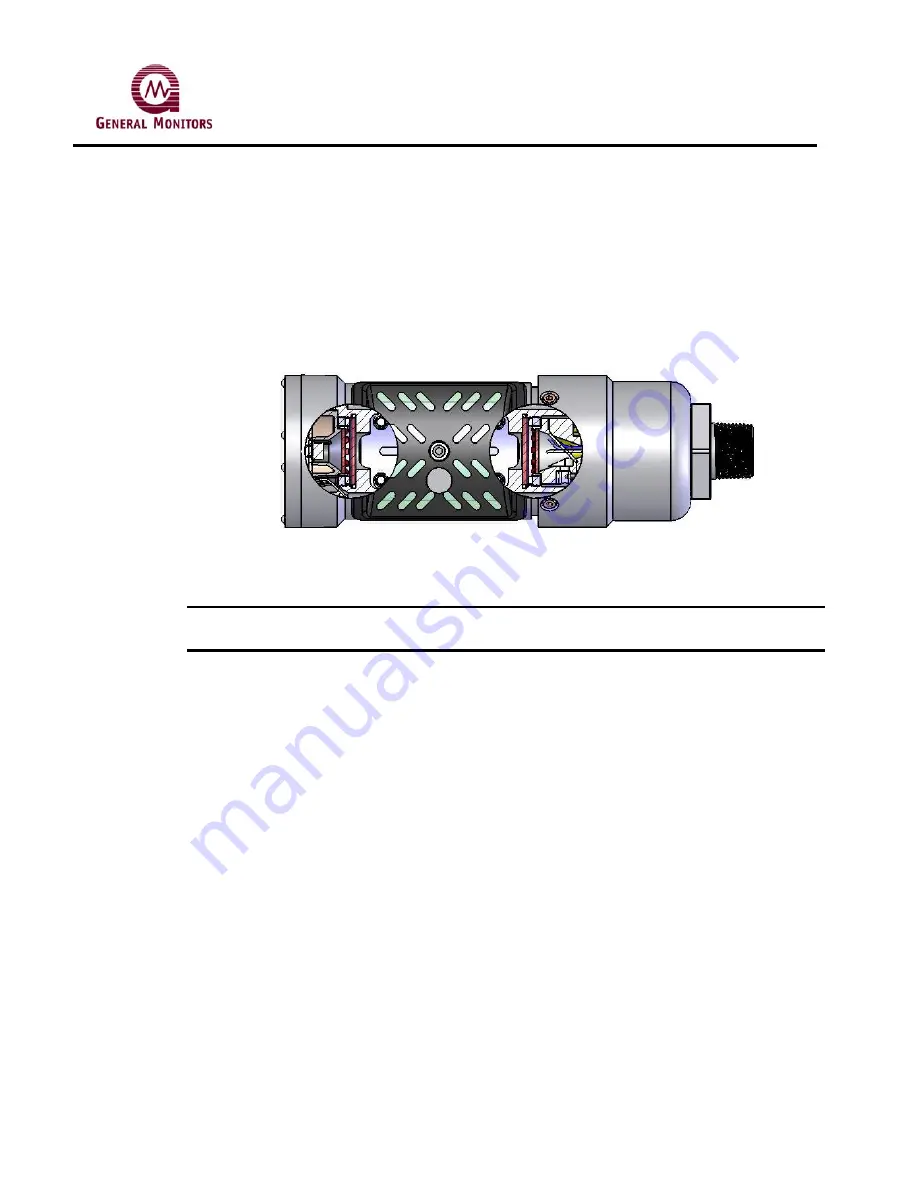

The IR400 optical windows can be cleaned by removing the splashguard that covers them,

then gently wiping them with a soft, clean cloth or cotton swab that has had a commercial

window cleaning solution applied; water or ethanol are examples of suitable solvents. You can

remove particulate matter from the IR400, detector accessories, and IR4000 units using an

appropriate halogen-free solvent, such as water or ethanol. Accessories should be thoroughly

dried with compressed air, if necessary, before refitting them to the detector.

Figure 9 IR400 Optical Window Locations

•

NOTE:

Do not clean the windows while an IR400 unit is zeroing or in recalibration

mode. The unit must be re-zeroed after cleaning.

5.3.2 Lubricating IR400 and IR4000 Units

If the neoprene rubber gasket (O-ring) in the cover of the IR4000 enclosure is found dry, it

should also be lubricated with the lubricant/sealant that is included with the IR400/IR4000 units,

or is available on order from General Monitors (P/N 916-062).

As an alternative to grease, PTFE (Teflon) tape may be used.

5.4 Storage

The Model IR400 Gas Detector and IR4000 Monitor System should be stored in a clean, dry

area, and within the temperature and humidity ranges noted for environmental specifications in

Section 9.3.3 Electrical Specifications for the IR400, and the separate user manual for the

IR4000. Insert the red dust caps into any vacant cable entry holes while the unit is stored.

Summary of Contents for IR400

Page 2: ......

Page 15: ...Model IR400 11 Figure 5b IR400 Mounting Dimensions with a European Box ...

Page 20: ...Model IR400 16 Figure 7 Wiring Diagram from IR400 to Control Equipment ...

Page 41: ...Model IR400 37 9 6 Engineering Documentation ...

Page 45: ...Model IR400 HART Field Device Specification for Point IR Gas Detector ...

Page 78: ...Model IR400 Infrared Point Detector for Hydrocarbon Gas Applications Modbus programming guide ...