Model IR400

28

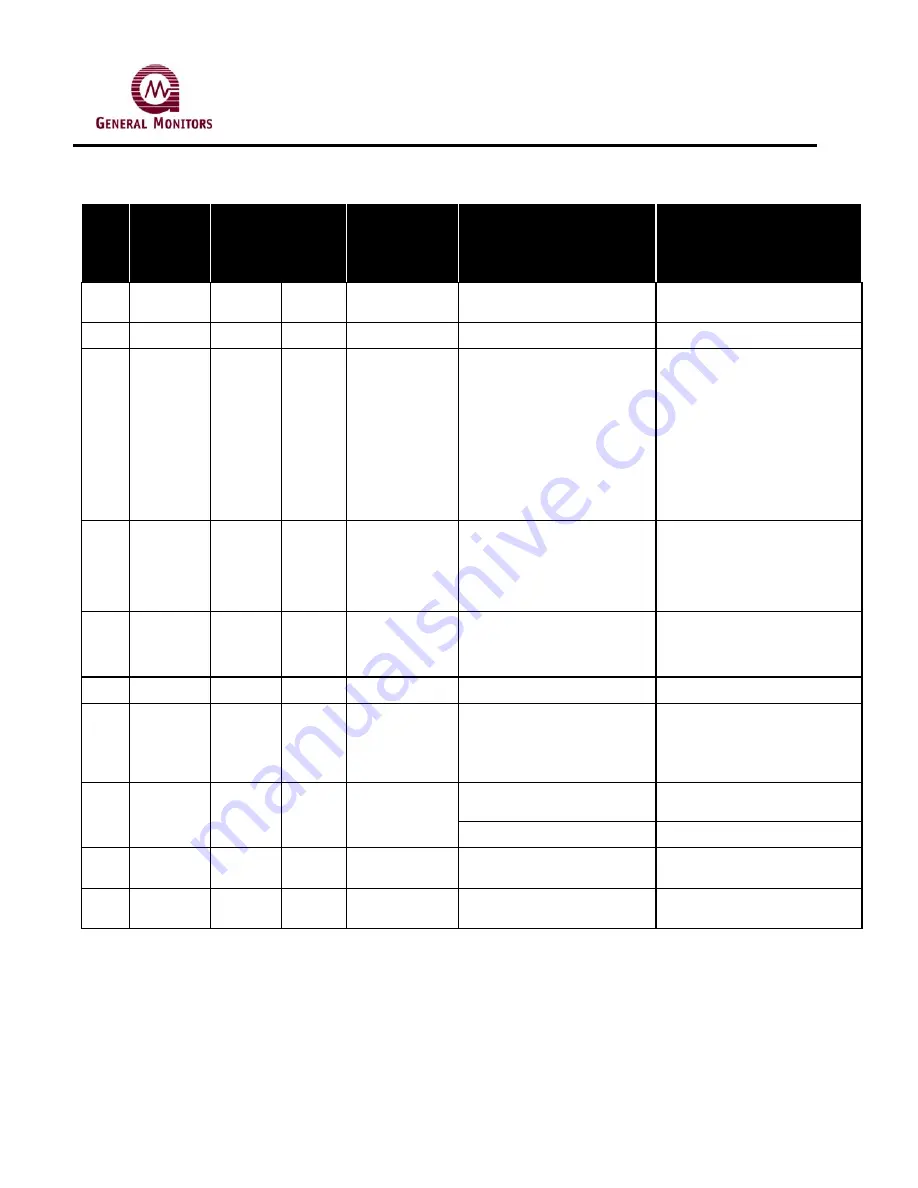

Table showing the fault conditions and corrective action required:

HART

non-HART

F0

Bits 3 & 14

2mA for 30s

then 1.25mA

2mA for 30s

then 0mA

Gas Concentration is

Excessively Negative

1)Fouling of the detector windows or beam

path is excessive and requires attention

1) Clean detector beam path and windows.

F1

Bits 0 & 1

2

2

Gas Concentration is

Negative

1) Detector windows or beam path are

beginning to be obscurred.

1) Clean detector beam path and windows.

1) Cal bottle empty and time-out occurred 1) Obtained filled CAL bottle and re-CAL.

2) Failed to remove gas at end of CAL and

time-out occurred.

2) Remove gas when directed.

3a) Check CAL cup for proper seating on

unit.

3b) Check CAL cup seal and replace CAL

cup if damaged.

4) Attempted to CAL with too much wind

resulting in unstable signal.

4) Calibrate at a much less windy time or

shield the unit and CAL cup from the wind.

1) Detector windows or beam path are

blocked by dirt, spider webbing or other

foreign matter.

1) Clean detector beam path and windows.

2) Detector or source failure.

2) The IR400 must be returned to the factory

or authorized service center for repair.

1) Incorrect communications set-up.

1) Ensure baud rate, data format and

address matches at both the IR400 and the

bus master.

2) Communications wiring open.

2) Check and correct wiring.

3) Communications wiring shorted.

3) Check and correct wiring.

F5

Bit 4

1.25

0

CAL Wire (brown)

Shorted

1) CAL Wire (brown) not in connector

1) Check and ensure proper connection of

wire to board connector

1) Power supply not outputing greater than

20VDC.

1) Check the supply voltage and replace

power supply if necessary

2) Voltage loss due to wiring.

2) Check the supply voltage at the IR400

field and adjust supply to +24VDC at the

IR400 or replace wiring with larger gauge.

1) Internal memory glitch

1) Cycle power, wait 2 minutes, if the fault

clears then check all menu settings and

recalibrate the IR400.

2) Internal error with the electronics.

2) Call your local General Monitors

representative for advice.

F8

Bit 7

1.25

0

Failed to Zero

1) Unstable signal due to gas present.

1) Ensure clean air is available for zeroing or

provide zero air to the IR400 during zeroing.

Bit 6

FAULT

CODE

DESCRIPTION

MODBUS FAULT

FLAG REGISTER

2

F2

Failed to Complete

Calibration

CORRECTIVE ACTION

ANALOG OUTPUT (mA)

2mA for 30s

then 0mA

1.25

0

1.25

0

3) Leaky CAL cup resulting in unstable

signal.

POSSIBLE CAUSE

1.25

F9

CAL Check Period

Exceeded

F6

Low Supply Voltage

1.25

F7

F3

Beam Block

2mA for 30s

then 1.25mA

F4

Communications Fault

(Applies to IR4000M

display only)

1) Test gas still present after gas check

completed.

1) Remove the gas

0

Bit 2

Bit 5

Bit 8

0

Bits 9 - 13 & 15

1.25

0

Electronics Error

Summary of Contents for IR400

Page 2: ......

Page 15: ...Model IR400 11 Figure 5b IR400 Mounting Dimensions with a European Box ...

Page 20: ...Model IR400 16 Figure 7 Wiring Diagram from IR400 to Control Equipment ...

Page 41: ...Model IR400 37 9 6 Engineering Documentation ...

Page 45: ...Model IR400 HART Field Device Specification for Point IR Gas Detector ...

Page 78: ...Model IR400 Infrared Point Detector for Hydrocarbon Gas Applications Modbus programming guide ...