Jet-Set JM-1000™

4

5.

Never run pump without water in it.

Operating the machine

without water will cause the pump to fail and void the warranty.

6.

Check for worn hose and components before each use.

Check that all fittings are secured before using jet.

Worn or

lose fittings can cause damage to the machine and injure the op-

erator.

7.

Protect machine and pump from freezing.

Storing or operating

the jet in temperatures below freezing can damage pump, hose

and other jet components. Store unit indoors or protect with anti-

freeze when not in use.

8.

Do not sit or stand on carrying case

.

9.

General Wire Spring Co. will not be liable for any changes

made to our standard machines or any components not pur-

chased from General Wire Spring Co.

AUTOMATIC UNLOADER

The JM-1000 Mini Jet is equipped with an Automatic Unloader to pro-

tect the pump. It prevents pressure overload in the event that the noz-

zle is clogged or spray wand trigger is off. A water sensor in the pump

will "sense" if the water is flowing and automatically turn off the power

off if the water stops flowing to protect the pump from damage. The

unit may shut off for 1 - 2 seconds while in operation to allow water to

prime the pump. Do not run the jet for more than 5 minutes with the

pump in bypass mode. Continuing to operate in bypass mode for ex-

tended periods will cause damage to the pump. Excessive tempera-

tures will damage the pump and void the warranty.

HOSE GUIDE

Hose Size (ID*)

Pipe Size

Typical Applications

1/8” (3.175mm)

Available in 30’ &

50’ lengths

1-1/2” - 2”

(38mm - 51mm)

Small lines, bathroom

sinks, tight bends

* Inside Diameter

JET NOZZLES

1. A variety of jet nozzles are available for drain cleaning. Each has a

different spray pattern and purpose. Some nozzles may have an

orifice in the front to cut through the stoppage. All will have holes

in the back to drive the hose down the line and clean the walls of

the pipe. A tight spray pattern (15°) has more driving power for

long runs, a wide spray pattern (30°) does a better job of cutting

the grease off of the walls of the pipe. A combination of nozzles

may be required to clear a line. Always turn off the machine and

turn off output valve before changing nozzles.

2. Make sure the nozzle you are using matches the pump size. A

3000 psi pump requires a different nozzle orifice than a 1500 psi

pump. Mismatching nozzles with pump size will either cause too

little pressure, which may not clear the drain, or too much pres-

sure, which may damage the machine.

3. Check nozzles before and after each use for clogged holes which

can cause pressure to increase to dangerously high levels and

damage the pump. A clogged hole can be cleared by simply using

the NCT Nozzle Cleaning Tool.

4. Use the nozzle selection guide to determine what nozzle you will

need for various applications.

JET HOSE

When selecting hose size, consider that pressure is lost as the

water travels down the length of the hose. As the length increases, the

pressure decreases. In addition, the smaller the diameter of the

hose, the greater the loss of pressure per foot will be. As an exam-

ple, a 2 GPM a 1/4” hose will lose 180 lbs. of pressure over 100 ft. of

hose, yet a 3/8” hose will only lose 25 lbs. of pressure over the

same length and at the same flow rate. It is important to select the

largest possible hose size in order to have as much pressure as

possible at the end of the hose.

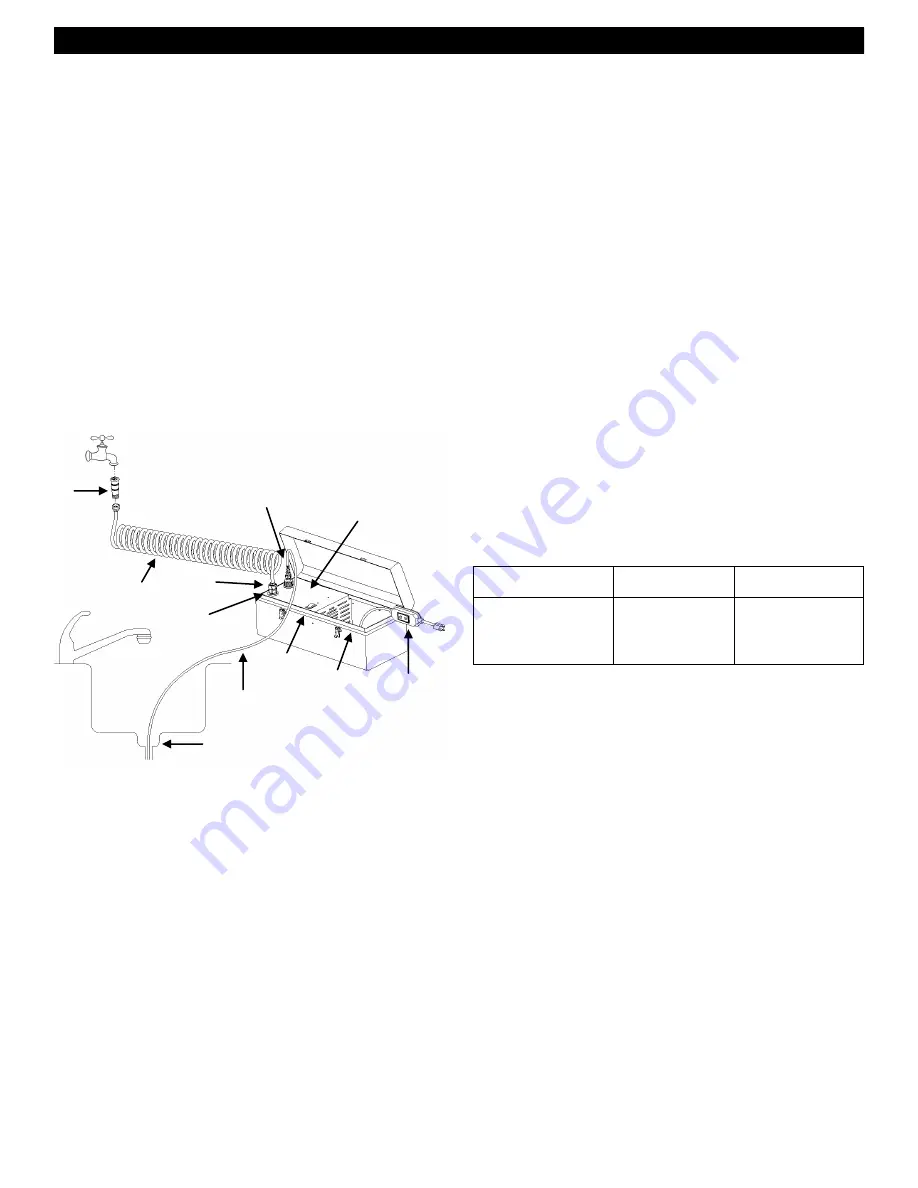

JM-1000 SPECIFICATIONS

1. Universal Faucet Adapter

2. Water Supply Hose

3. Water Inlet

4. Shut Off Valve

5. High Pressure Outlet

6. Pump & Motor (inside)

7. Power Switch

8. Storage Compartment

9. GFCI Power Cord

10. High Pressure Jet Hose

11. Drain

3

5

2

1

10

7

6

8

11

9

4