Speedrooter XL

®

7

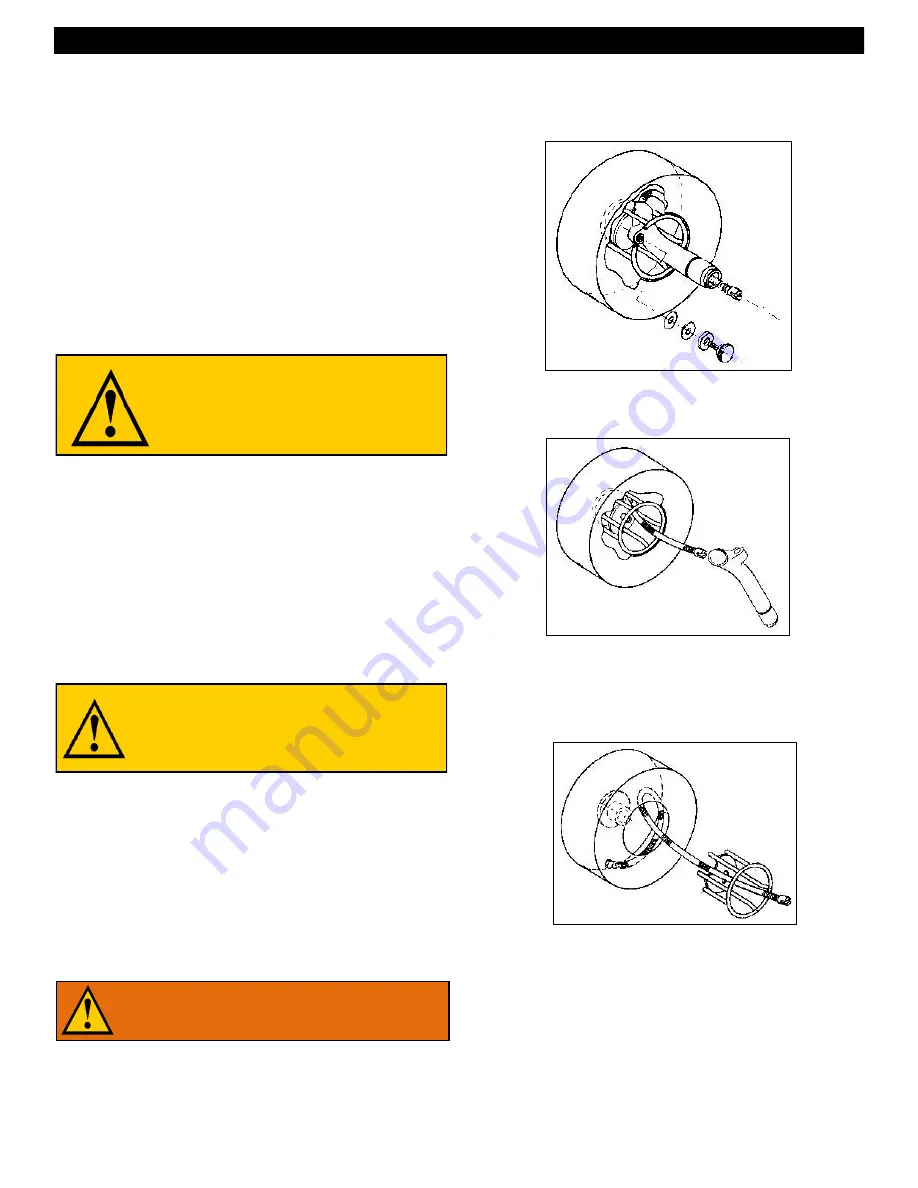

2. Set drum down so that distributor tube is pointing up. Unscrew

knob at the back of distributor tube. (See Figure 1.) This un-

locks the distributor tube from the drum shaft. Be careful not to

lose the thrust bearing and race attached to the knob.

3. Slide the distributor tube off the shaft and out of the drum. (See

Figure 2.)

The tension of the cable will force the tube to the side of the

drum as you pull it out; so keep some pressure against the cable

as you pull the tube out. After tube is out, pull out the inner drum

cage. (See Figure 3.) Pull out enough cable to eliminate the

tangle.

4. After the cable is straightened out, slide the inner drum cage

back into place. (Figure 3.) Then slide distributor tube back so

that curved section is adjacent to crescent-shaped notch in inner

drum cage and back of distributor tube fits over shaft in center of

drum. (Figure 2.) Keep pressing down on distributor tube as you

tighten knob

with

thrust bearing and races. (Figure 1.) This

holds tube into place. You can now put the drum back on the

machine.

Figure 1

Figure 2

Figure 3

DO NOT USE REVERSE TO PULL THE CABLE

OUT OF THE DRAIN.

RUNNING MACHINE IN REVERSE CAN

CAUSE THE CABLE TO TANGLE IN THE

DRUM

.

10. Be careful not to let the cutter get caught in the stoppage as you

work through it. This can cause kinking and breaking of the ca-

ble. When you feel the cable starting to twist in your hands, stop

the machine and retract the cable. This will free the cutter from

the obstruction. Then allow the cable to move forward slowly into

the stoppage. Remember, no cutting takes place when the

blades stop turning.

11. After the line has been opened, retract the cable by moving the

feed lever up. Make sure the motor switch is in the

forward

posi-

tion. This is important to prevent the cable from tangling in the

drum or in the line.

12. When the cutter is near the drain opening, take your foot off the

pedal to stop drum rotation. Never retract the cutter from drain

while cable is rotating. The cable could whip and cause serious

injury.

DISCONNECT MACHINE FROM POWER SOURCE

BEFORE UNTANGLING CABLES

DO NOT RUN MOTOR IN REVERSE FOR MORE

THAN A FEW SECONDS AT A TIME SINCE THIS

COULD CAUSE THE CABLE TO KINK OR TANGLE

IN THE DRUM.

SPECIAL OPERATIONS

IF CABLE GETS CAUGHT IN LINE

The motor can be reversed to free the cable if it gets caught in line.

(Note: if using Power Cable Feed, putting motor in reverse will cause

the feed control lever to operate opposite of normal.)

1. Move motor switch to the reverse position.

2. Depress the foot pedal while pulling on the cable.

3. After cable is loose, move switch back into forward position.

IF CABLE TANGLES IN DRUM

This is caused by using too much pressure when feeding the cable or

feeding the cable into the line while running the machine in reverse.

To untangle the cable, rotate the drum in opposite direction. This will

usually get the cable to lie in the drum properly.

If the cable has become badly tangled, which shouldn’t occur if used

properly, it can be straightened out by removing the distributor tube

from the machine. To do this:

1. Remove drum from machine frame. (See TO REMOVE DRUM.)

Summary of Contents for Speedrooter XL

Page 11: ...Speedrooter XL ...