5 - 4

Troubleshooting Guide

Excessive pressure drop across dryer.

1.

Badly broken, dusted or fouled desiccant.

2.

Inlet flow rate (SCFM) is exceeding the

dryer’s design flow rate as specified on the

Dryer Specification Label located on the in-

side cover of the dryer system control enclo-

sure.

3.

Desiccant retaining screens are clogged or

fouled.

4.

Inlet and/or outlet pressure gauges are out

of calibration, or damaged.

Chamber depressurization (prior to each regen-

eration cycle) is excessively loud.

1.

The purge exhaust flow restrictor is dam-

aged, or not fully seated.

1.

Shutdown and Depressurize Dryer. Inspect desiccant

through fill ports and replace if badly broken, dusted or fouled.

Note: If the “normally white” desiccant is fouled or discolored,

inspect prefilter cartridges and drain valve or trap.

2.

Reduce the inlet flow rate as necessary to meet the dryer’s de-

sign flow rate.

3.

Shutdown and Depressurize Dryer. Drain desiccant from

chamber. Inspect retaining screens through fill and drain ports

and clean if fouling is noted. Investigate and remedy source of

fouling.

CAUTION: Desiccant may be reinstalled if it is not fouled or

badly broken.

4.

Shutdown and Depressurize Dryer. Replace damaged,

faulty or out-of-calibration gauges.

1.

Shutdown and Depressurize Dryer. Proceed as follows:

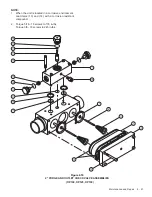

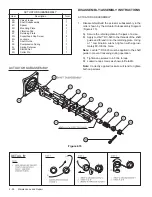

a) For Model OP250 only.

1.

Provide adequate support for muffler and flow

restrictor assembly. Remove flow restrictor assem-

bly from lower flange by equally loosening flange bolts.

Ensure that the method of support is prepared to

accept the Muffler’s full weight when the last bolt

is removed (see following CAUTION).

CAUTION: Exercise caution when lowering flow

restrictor and muffler to prevent damaging control tub-

ing, and the Purge Pressure Indicator.

2

Remove, clean and inspect the “spring and orifice-

type” flow restrictor. Install a new flow restrictor if dam-

age is noted.

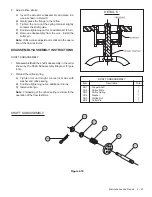

Important: When installing Flow Restrictor, its

springs MUST be fully seated in the spring recep-

tacle. This MUST be accomplished for proper opera-

tion.

3

Reinstall muffler and flow restrictor in the reverse order

of removal.

PROBLEM/POSSIBLE CAUSE

CHECKS AND REMEDY