Maintenance and Repair

4 - 7

4.6

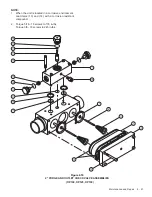

Moisture Indicator Recharging

Procedure

Note: Dryer shutdown is not necessary to perform the fol-

lowing procedure and can be accomplished without remov-

ing the entire assembly.

1.

Close the Moisture Indicator Supply Valve, and en-

sure that the Moisture Indicator has fully depressur-

ized through bleed valve [5] before proceeding to step

#2 for disassembly. (See following WARNING.)

WARNING!

Ensure that Moisture Indicator is fully depressur-

ized before attempting disassembly. Failure to

do so may result in serious personal injury and/or

equipment damage.

2.

Remove sight dome assembly (items [2], [4], [6], [7],

and [9]) from body [8] by turning screw [6] counter-

clockwise.

3.

Remove screw [6] from sight dome [2] by exerting

pressure on screw’s threaded end. Drain granular

indicator.

4.

Remove porous disc [4] and clean sight dome. (see

following CAUTION.)

CAUTION: Sight Dome [2] is an acrylic plastic. Do

Not clean with any type of solvent.

5.

Replace O-ring [9], and re-install screw [6] in sight

dome [2].

6.

Carefully pour new granular indicator into sight dome

[2]. Slide porous disc [4] into place.

7.

Replace O-ring [7] and re-install sight dome assembly

(items [2], [4], [6], [7], and [9]) in body [8].

8.

Fully open the moisture indicator’s gas supply valve

(not shown).

9.

Adjust bleed valve [5] until only a very slight constant

gas bleed valve is felt exhausting from valve’s bleed

port. Ensure that granular indicator remains motion-

less after final adjustment.

Figure 4.2

MOISTURE INDICATOR