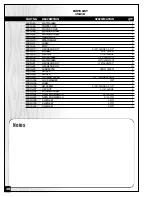

FRONT TABLE INCLINATION ADJUSTMENT

The front table can be inclined left or right for sanding

irregular workpieces.

1.

Loosen the two lock knobs

and raise or lower one

end of the table by hand either left or right

.

2.

Re-tighten the lock knobs to lock the table in position.

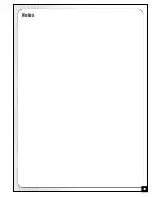

AUXILIARY TABLE HEIGHT ADJUSTMENT

Adjusting the height of the auxiliary table allows an even

wearing of the sanding belt surface by allowing you to

use different sections of the belt depending on the height

of the workpiece.

1.

Loosen the locking lever

located on the auxiliary

table mounting bracket.

2.

Raise or lower the auxiliary table by hand

and

tighten the locking lever.

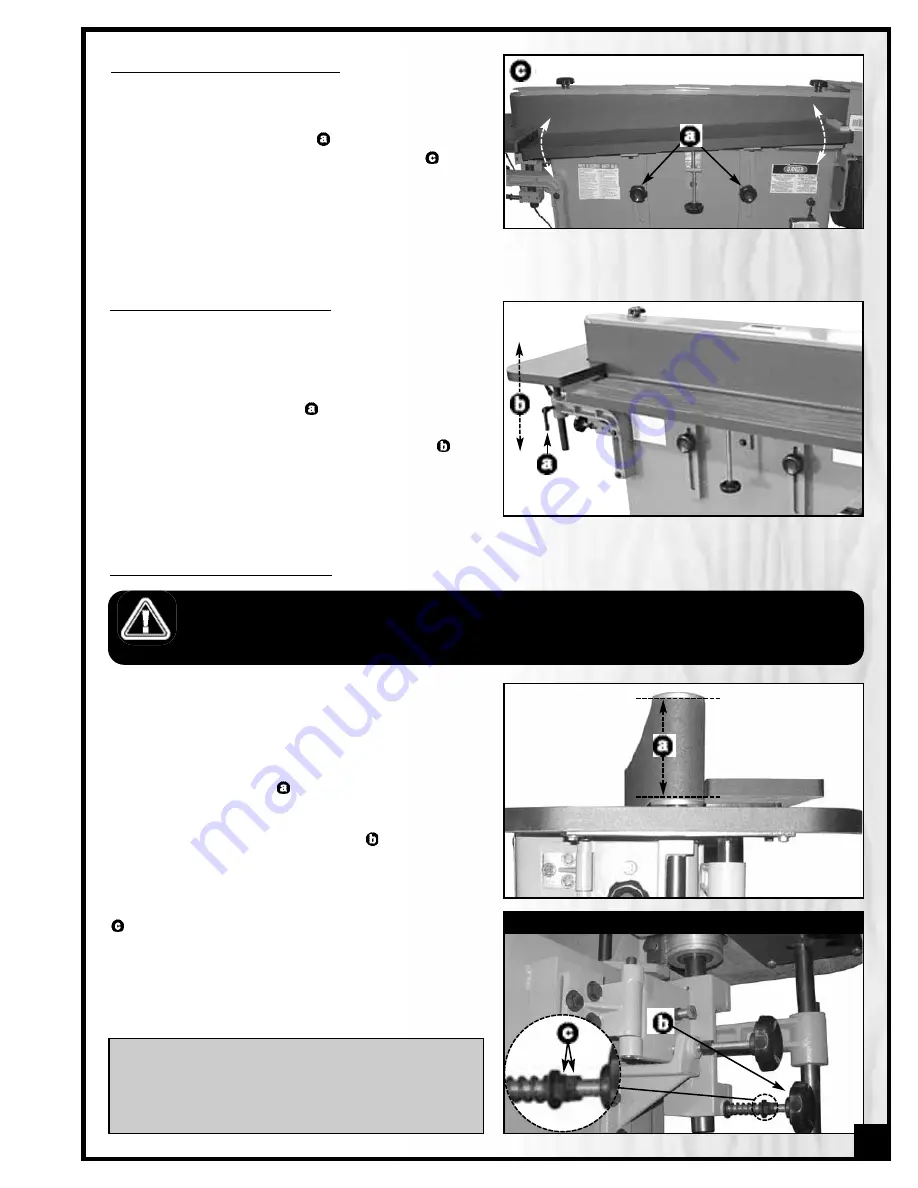

SANDING BELT TRACKING ADJUSTMENT

DO NOT ATTEMPT TO PERFORM ANY ADJUSTMENT WHILE THE MACHINE IS RUNNING. ALWAYS TURN OFF AND UNPLUG THE SANDER

BEFORE PERFORMING ANY ADJUSTMENT.

KEEP HANDS WELL AWAY FROM THE SANDING BELT AND ALL MOVING PARTS WHEN THE SANDER IS RUNNING.

AUXILIARY TABLE UNDERSIDE VIEW

Though not essential, proper belt tracking (having the

belt running straight as evenly on the drums as possible)

can prolong belt life and avoid having the belt slip off

during operation.

1.

Turn the sander on for 5-10 seconds to visually con-

firm the belt tracking

.

If the belt is not tracking straight, adjust as follows.

2.

Turn the tracking adjustment knob

:

• Counter-clockwise to adjust the tracking upward;

• Clockwise to adjust the tracking downward.

Note: If further adjustment is required, tighten the lock nuts

to obtain more spring compression.

3.

Turn on the machine for 5-10 seconds to visually

confirm the belt tracking.

4.

As needed, repeat this adjustment process until the

belt is tracking evenly on the drums.

Note: Belt tracking adjustments may be neces-

sary after changing or replacing a sanding

belt, to counterbalance for unevennesses be-

tween sanding belts.

13

Summary of Contents for 15-010 M1

Page 21: ...Notes 21...