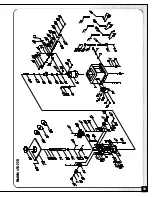

Step 3

If the table needs adjustment loosen both lock levers

and readjust the table position until the square is flat

against the table and the sanding drum. To allow

for more or less rear tilt adjust the table stop rod as

needed.

Step 4

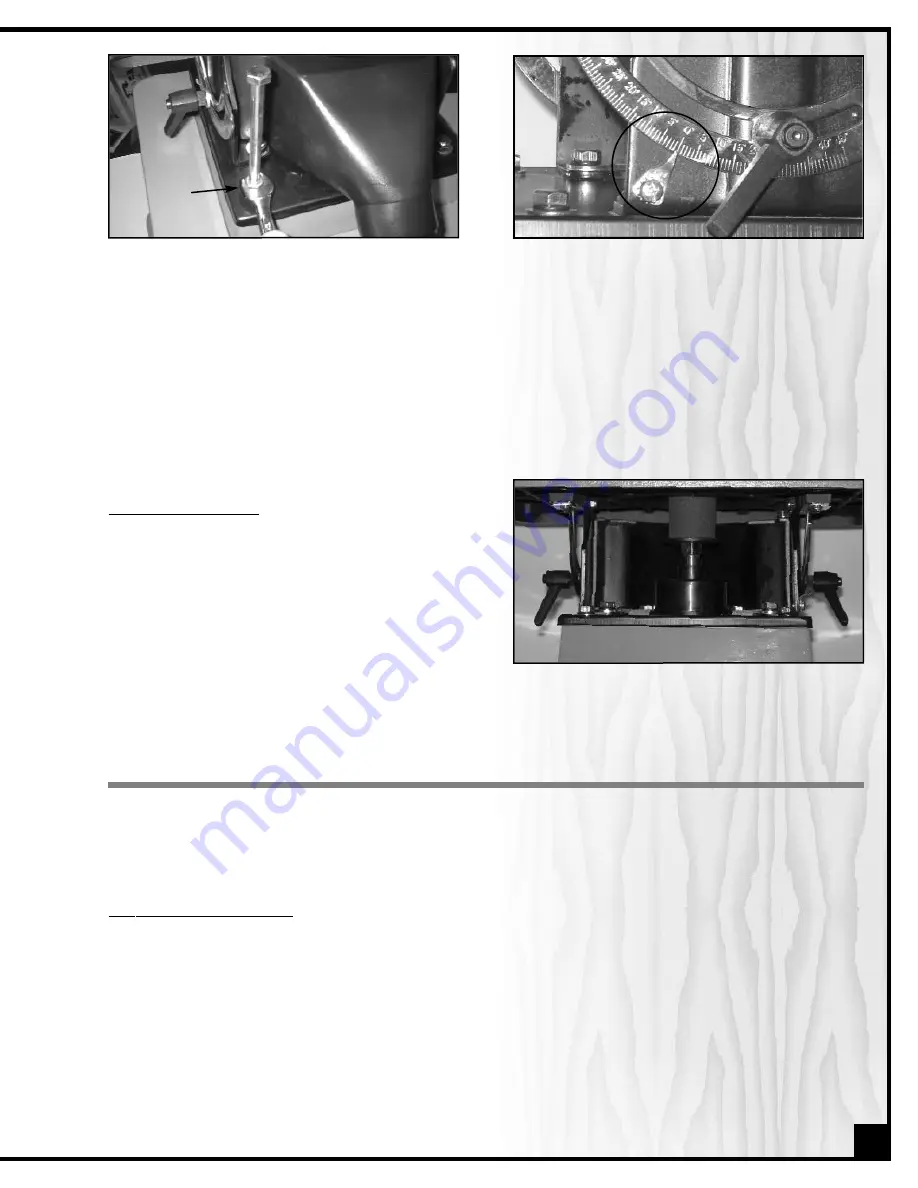

Make sure the pointer reads 0°. If the pointer needs

to be adjusted loosen the screw and adjust to the

correct position.

Step 5

Once the table has been adjusted and locked in place at 90° adjust the 90° table stop rod to butt against the under-

side of the table allowing you to return to 90° repeatedly without further adjustments.

SETUP FOR BEVEL SANDING

1.

Make sure the correct oblong opening table insert is in

place. See the accompanying SELECTION GUIDE

(page 10) to select the correct TABLE INSERT for the

spindle being used.

2.

Loosen both locking levers and tilt the table until the

pointer is at the desired angle.

3.

Hold the table in place and tighten both locking levers.

CHANGING SANDING SLEEVES

Make sure that the switch is in “OFF” position and that the power cord is unplugged.

Note: Installing or changing sanding sleeves is best performed with the spindle removed from the machine.

Refer to page 8 - “Installing the sanding sleeves” for step by step instructions.

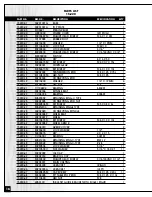

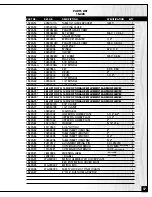

REPLACEMENT SANDING SLEEVES

Replacement sleeves can be purchased in varying grits (depending on availability) from any local tool or abrasives

dealer in the following sizes:

•

1/4" DIAMETER X 6 " LONG

•

1-1/2" DIAMETER X 5 1/2 " LONG

•

1/2" DIAMETER X 6 " LONG

•

2” DIAMETER X 5.5” LONG

•

5/8" DIAMETER X 6 " LONG

11

90° TABLE

STOP ROD

Summary of Contents for 15-220

Page 15: ...15 Mod le 15 220...