www.GenieCompany.com/commercial

|

800.843.4084

©2012 The Genie Company

|

GCL-Hss

GCL-H

|

STANDARD-DUTY HOIST OPERATOR

1. Max Door Weight and not the square footage, is the critical factor in selecting the proper operator.

2. Max Door Height 24’

3. For “Commercial Steel Insulated” category, various “backer” options are available. The chart above is based in all cases on the thickest backer available.

4. “PU-FIP” stands for “polyurethane, foamed-in-place.” If no notation is present, insulation is “polystyrene laid-in-place.”

Notes:

Accessories and Options

• Timer to Close Module

Timed close set via the LCD display from 2 seconds up to 5 minutes. Includes

pre-close warning contacts, timer hold input, auxiliary open input, normally closed

safety input, and monitored edge input.

• Auxiliary Output Module

Provides relay contacts at the open, close, and mid-stop limits. Contacts for

5-minute lamp, and “ADA” contacts set via LCD display to warn during opening,

closing or both.

• Intellicode

®

I Transmitters

Available in single up to four button, or open/close/stop models.

• Environmental Modifications

Totally enclosed non-ventilated, or fan-cooled motors available - Must be ordered

from the factory. Nema 4 or Nema 4X environmental modifications

- Must be ordered from the factory.

• UL325-2010 Approved Reversing Devices

The installation of a monitored external entrapment device is required for

momentary contact close operation on all commercial door operators. Only the

following devices, when purchased through Genie, are UL-Approved for use to meet

this requirement:

• Safe-T-Beam

®

Photoeye Kit with adjustable bracket P/N 38176R.S

1

• Impact-protected Commercial Photoeye Kit P/N OPAKPE.S

• MillerEdge ME/MT/CPT (DC or T3) 2-wire edge sensor. Must be used with

TCM (OPABTCGX.S) or Interface Module (OPAKMEIGX.S).

• Nema 4 Photoeyes P/N OPAKPEN4GX.S

1

— Default device when operator is ordered.

Construction

• Motor

AC continuous-duty motor. Motor replaceable without changing limits.

Thermally protected.

• Drive

Primary — TensiBelt™ auto tensioning poly-V J belt.

Secondary — chain and sprocket reduction.

• Brake

24VDC disc brake standard on 3/4 and 1 HP models; option on

½ HP models

• Friction Clutch

Adjustable clutch to help protect against door and operator damage.

• Precision Radial Ball Bearings

Included in critical areas throughout the powertrain.

• Emergency Hoist Manual Operation

Electrically interlocked manual hoist with floor level disconnect.

• Pre-wired to accept:

- Monitored entrapment device such as photo eyes.

- Single or 3-button control stations.

- External interlock switches.

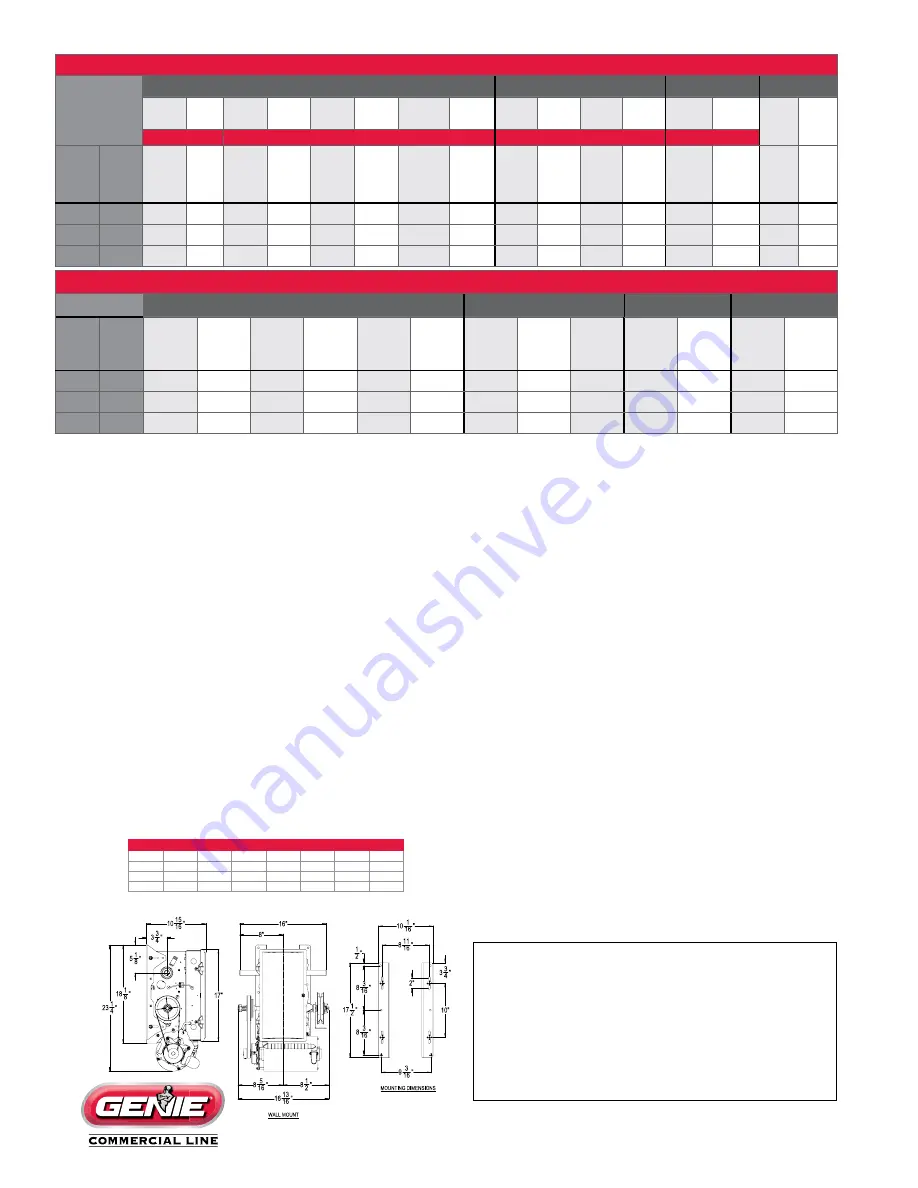

MAX DOOR SIZE (SQ*FT) - ROLLING

Door Series

Steel Non-Insulated

Steel Insulated

Counter Doors

Grilles

Model

Max

Door Wt.

(lbs.)

16GA.

18GA.

20GA.

22GA.

24GA.

26GA.

18GA.

20GA.

22GA.

Aluminum

STL/SST

Aluminum

STL/SST

1/2 HP

998

297

333

333

416

476

476

238

238

274

126

126

350

240

3/4 HP

1220

359

419

419

552

618

N/A

276

276

309

126

126

450

310

1 HP

1440

388

461

461

606

621

N/A

297

296

382

126

126

610

450

MAX DOOR SIZE (SQ*FT) - SECTIONAL

Door Series

Commercial Steel Insulated & Non-Insulated

Thermospan

®

ThermoMark

™

Aluminum

216

216

Ins.

220

220 Ins.

2415

2415

Ins.

2411

2411

Ins.

125

150

200

200-20

5150

5200

451

452

Flush

Ribbed

Insulated

Insulated

Model

Max

Door Wt.

(lbs)

16GA.

16GA.

Ins.

20GA.

Steel

20GA.

Ins.

24GA.

24GA.

Ins.

Nominal

24GA.

Nominal

24GA.

Ins.

PU-FIP

PU-FIP

1.38”

PU-FIP

2”

PU-FIP

2”

20GA.

Ext.

PU-FIP

Raised

Panel

1.38”

PU-FIP

Raised

Panel

2”

1/8”

Glass

1.38”

1/4” or

1/2”

Glass

1.38”

1/2 HP

1120

256

220

370

256

440

340

320

320

256

360

400

300

400

380

360

240

3/4 HP

1370

330

256

440

310

530

400

320

320

256

450

450

370

460

440

400

330

1 HP

1620

380

280

500

370

570

410

320

320

256

480

480

420

500

480

400

400

Dealer Imprint Area

AMPERAGE RATING - 60Hz

Hp

115V 1Ø 208V 1Ø 230V 1Ø 208V 3Ø 230V 3Ø 460V 3Ø 575V 3Ø

1/2

10

5

5

3

3

3

2

3/4

11

6

6

3

4

3

2

1

14

7

7

4

4

3

2