www.GenieCompany.com/commercial

|

800.843.4084

©2012 The Genie Company

|

GCL-MJss

13 78 "

6 34 "

7 3

16 "

6 58 "

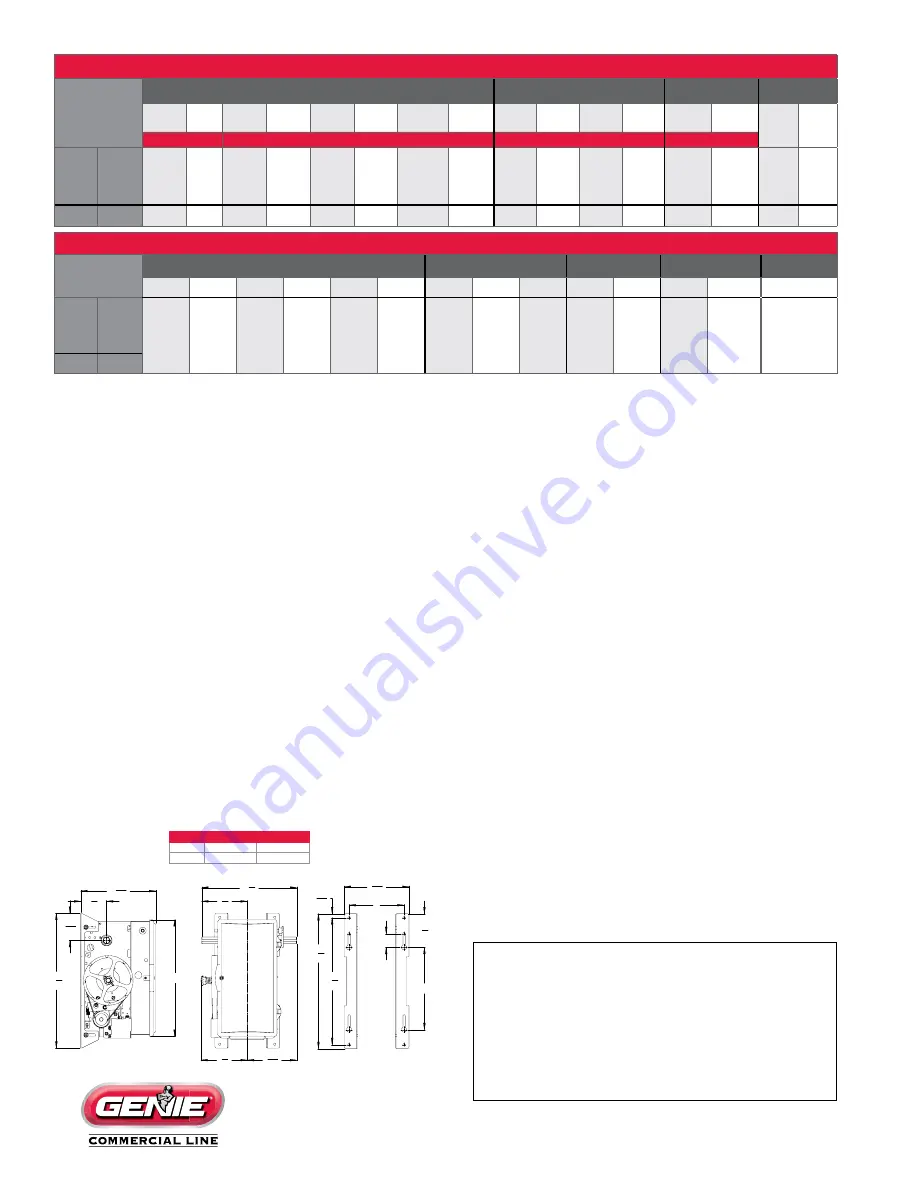

SECTIONAL WALL MOUNT

10 15

16 "

3 34 "

3 15

16 "

19 58 "

17"

19 58 "

18 12 "

9

16 "

8"

2"

12"

9 7

16 "

4 78 "

MOUNTING DIMENSIONS

REVISIONS

ER

REV

DESCRIPTION

DATE APPROVAL

501348

-

ORIGINAL ISSUE

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

GMXJ TECHNICAL INFO

-

NOTES: (UNLESS OTHERWISE SPECIFIED)

11/10/11

FINISH

MATERIAL

HOLES:

< Ø.251 = .003

Ø.251-Ø.500 = .003

> Ø.500 = .003

112213

INCHES

WDR 10/19/2011

WDR

11/9/11

DO NOT SCALE

A SUBSIDIARY OF OVERHEAD

DOOR CORPORATION

TOLERANCES:

DRAWN

112213-GMXJ-SECT

INTERPRET DIMS & TOLS

PER ASME Y14.5M

DIMS CIRCLED WITH

SYMBOL '

' ARE CRITICAL

TO QUALITY DESIGN

FEATURES & MUST MEET

APPLICABLE IN-PROCESS

INSPECTION STANDARDS.

ALL DIMS ARE IN

UNLESS OTHERWISE SPECIFIED

SCALE 1:2

DWG NO.

SIZE

DESCRIPTION

APPROVALS

DATE

ALL GEOMETRY GOVERNED BY 3D CAD DATABASE:

APPROVED

CHECKED

.X = ±.1

.XX = ±.01

.XXX = ±.005

ANGULAR = ±1

SHEET 1 OF 2

THIRD ANGLE PROJECTION

ALLIANCE, OHIO

D

PLOTTED: 10/19/11

MS

THE DRAWINGS AND ALL OTHER

INFORMATION CONTAINED HEREIN ARE

THE CONFIDENTIAL PROPRIETARY

PROPERTY OF OVERHEAD DOOR

CORPORATION, INCLUDING ITS

AFFILIATED SUBSIDIARIES AND

AFFILIATES. THIS DRAWING

INFORMATION, IN WHOLE OR IN PART,

MAY NOT BE COPIED IN ANY MANNER OR

DISCLOSED TO ANYONE WITHOUT PRIOR

WRITTEN CONSENT OF OVERHEAD DOOR

CORPORATION. DISCLOSURE OF ANY

DRAWING OR INFORMATION IS INTENDED

NOT TO AND SHALL NOT OPERATE AS A

LICENSE OR AUTHORIZATION TO USE IT

FOR ANY PURPOSE WITHOUT SPECIFIC

WRITTEN CONSENT OF OVERHEAD DOOR

CORPORATION.

P/N 112213-0001

GCL-MJ

|

MEDIUM-DUTY JACKSHAFT OPERATOR

1. Max Door Weight and not the square footage, is the critical factor in selecting the proper operator.

2. Max Door Height 16’

3. For “Commercial Steel Insulated” category, various “backer” options are available. The chart above is based in all cases on the thickest backer available.

4. “PU-FIP” stands for “polyurethane, foamed-in-place.” If no notation is present, insulation is “polystyrene laid-in-place.”

Notes:

Accessories and Options

• Timer to Close Module

Timed close set via the LCD display from 2 seconds up to 5 minutes.

Includes pre-close warning contacts, timer hold input, auxiliary open

input, normally closed safety input, and monitored edge input.

• Auxiliary Output Module

Provides relay contacts at the open, close, and mid-stop limits. Contacts

for 5-minute lamp, and “ADA” contacts set via LCD display to warn during

opening, closing or both.

• 315Mhz Receiver Module

IntelliCode

®

I radio receiver that is 315Mhz and capable of storing 50

single-button and/or 50 open-close-stop transmitters with the ability to

add and/or delete transmitters individually, identify and store activating

transmitter ID(s).

• UL325-2010 Approved Reversing Devices

The installation of a monitored external entrapment device is required

for momentary contact close operation on all commercial door operators.

Only the following devices, when purchased through Genie, are UL-

Approved for use to meet this requirement:

• Safe-T-Beam

®

Photoeye Kit with adjustable bracket

P/N 38176R.S

1

• Impact-protected Commercial Photoeye Kit P/N OPAKPE.S

• MillerEdge ME/MT/CPT (DC or T3) 2-wire edge sensor. Must be

used with TCM (OPABTCGX.S) or Interface Module (OPAKMEIGX.S).

• Nema 4 Photoeyes P/N OPAKPEN4GX.S

1

— Default device when operator is ordered.

Construction

• Motor

1/2 HP, AC capacitor start/run motor. Motor replaceable without

changing limits.

• Brake

AC solenoid-actuated band brake.

• Drive

Primary — TensiBelt

™

auto tensioning Poly-V J belt.

Secondary — chain and sprocket reduction.

• Friction Clutch

Adjustable clutch to help protect against door and

operator damage.

• Precision Radial Ball Bearings

Included in critical areas throughout the powertrain.

• Emergency Manual Operation

Pull-cord disconnect disengages drive allowing door to be moved

manually while maintaining limits.

• Pre-wired to accept:

- Monitored entrapment device such as photo eyes.

- Single or 3-button control stations.

- External interlock switches.

MAX DOOR SIZE (SQ*FT) - SECTIONAL

Door Series

Commercial Steel Insulated & Non-Insulated

Thermospan

®

ThermoMark

™

Aluminum

216

216

Ins.

220

220

Ins.

2415

2415

Ins.

2411

2411

Ins.

125

150

200

200-20

5150

5200

451

452

Flush

Ribbed

Insulated

Insulated

Model

Max

Door

Wt.

(lbs.)

16GA.

16GA.

Ins.

20GA.

Steel

20GA.

Ins.

24GA.

24GA.

Ins.

Nominal

24GA.

Nominal

24GA.

Ins.

PU-FIP

PU-FIP

1.38”

PU-FIP

2”

PU-FIP

2”

20GA.

Ext.

PU-FIP

Raised

Panel

1.38”

PU-FIP

Raised

Panel

2”

1/8”

Glass

1.38”

1/4” or

1/2”

Glass

1.38”

1/2 HP

620

170

120

230

160

270

200

300

256

256

256

240

160

256

256

210

144

MAX DOOR SIZE (SQ*FT) - ROLLING

Door Series

Steel Non-Insulated

Steel Insulated

Counter Doors

Grilles

Sheet Door

16GA.

18GA.

20GA.

22GA.

24GA.

26GA.

18GA.

20GA.

22GA.

Aluminum

STL/SST

Aluminum

STL/SST

26GA.

Model

Max

Door

Wt.

(lbs.)

197

246

246

338

394

394

148

148

197

126

126

300

200

256

1/2 HP

580

Dealer Imprint Area

AMPERAGE RATING 1Ø 60Hz

Hp

115V

230V

1/2

6.5

3.1