Section 3 • Scheduled Maintenance Procedures

3 - 20

GR-20J • GR-26J

Part No. 227656

September 2016

CHECKLIST

B

PROCEDURES

B-12

Perform Hydraulic Oil Analysis

Genie specifications require that this procedure be

performed every 250 hours or quarterly, whichever

comes first.

Replacement or testing of the hydraulic oil is

essential for good machine performance and

service life. Dirty oil may cause the machine to

perform poorly and continued use may cause

component damage. Extremely dirty conditions

may require oil changes to be performed more

often. Refer to Section 2,

Specifications

.

Before replacing the hydraulic oil, the oil may be

tested by an oil distributor for specific levels of

contamination to verify that changing the oil is

necessary.

If the hydraulic oil is not replaced at the two

year inspection, test the oil quarterly. Replace

the oil when it fails the test.

See E-1,

Test or

Replace the Hydraulic Oil.

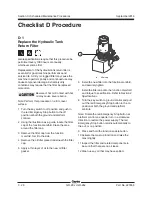

B-13

Inspect the Breather Cap

Genie specifications require that this procedure be

performed every 250 hours or quarterly, whichever

comes first. Perform this procedure more often if

dusty conditions exist.

A free-breathing hydraulic tank cap is essential for

good machine performance and service life. A dirty

or clogged cap may cause the machine to perform

poorly. Extremely dirty conditions may require that

the cap be inspected more often.

1 Open the turntable cover at the hydraulic power

unit side of the machine.

2 Locate and remove the breather cap from the

hydraulic tank.

3 Check the breather cap for proper venting.

Result: Air passes through the breather cap.

Proceed to step 5.

Result: If air does not pass through the cap,

clean or replace the cap. Proceed to step 4.

Note: When checking the hydraulic tank breather

cap for venting, air should pass freely through the

cap.

4 Using a mild solvent, carefully wash the cap

venting system. Dry using low pressure

compressed air. Repeat this procedure

beginning with step 3.

5 Install the breather cap onto the hydraulic tank.