Section 3 • Scheduled Maintenance Procedures

Part No. 227656

GR-20J • GR-26J

3 - 23

September 2016

CHECKLIST

B

PROCEDURES

B-16

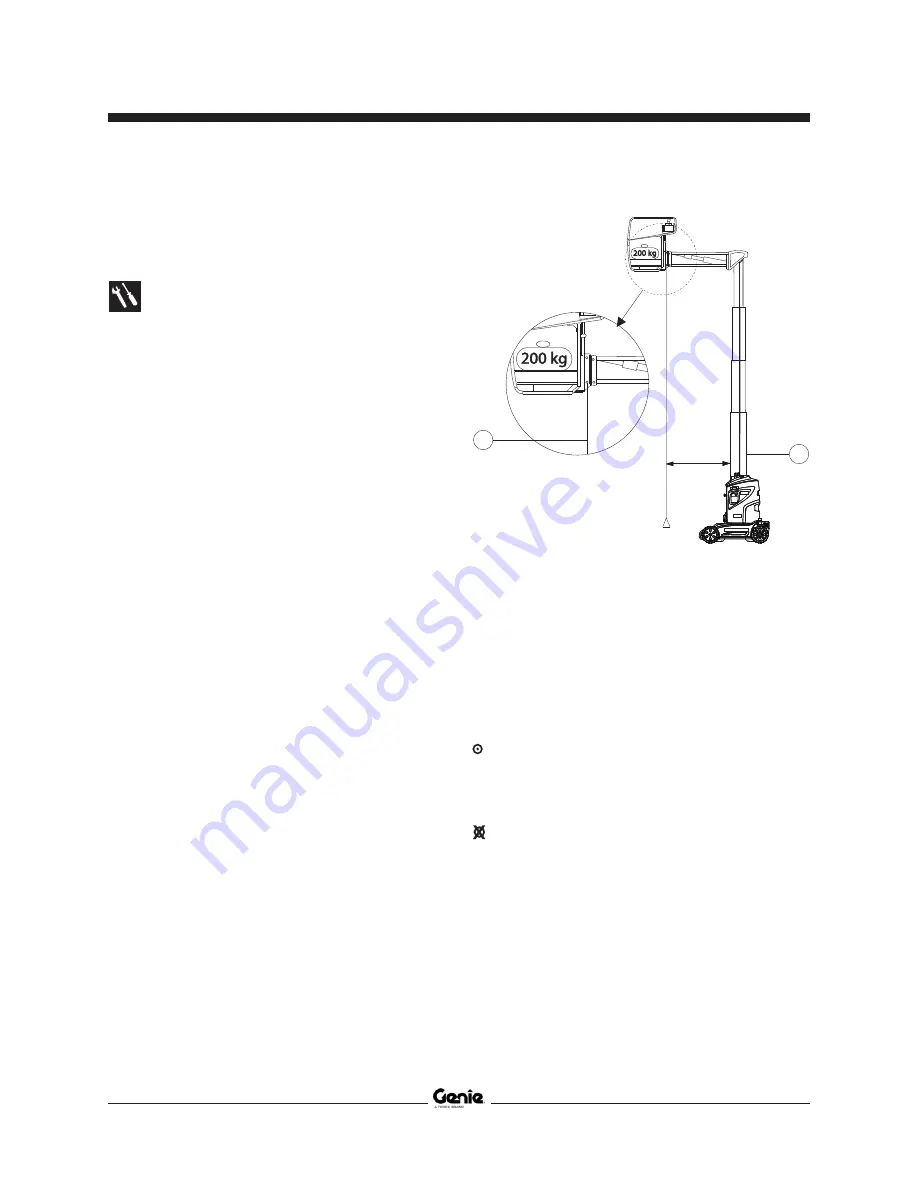

Inspect the Mast Wear Pads

Genie specifications require that this procedure be

performed every 250 hours or quarterly, whichever

comes first.

Mast wear pads should always be in good

condition and greased for good machine

performance and service life. A damaged wear

pads may cause the unsafe machine operation.

Note: Perform this procedure with the machine on

a firm, level surface that is free of obstructions.

Note: Perform this procedure in a location that is

sheltered from the wind.

1 Using the illustration as a guide, install a plumb

line of a suitable length onto the platform.

2 Using a suitable lifting device, place a

440 lbs / 200 Kg test weight in the center of the

platform. Secure the weight to the platform.

3 Turn the key switch to ground control and pull

out the red Emergency Stop button to the on

position at both the ground and platform

controls.

Note: Rotate the red Emergency Stop button at

platform control one quarter turn in a clockwise

direction to restore the power supply. The red

Emergency Stop button returns automatically to

the out, or on position.

a

number 1 mast

b

plumb line

4 Raise the jib boom to a horizontal position.

5 Activate the mast up function and fully raise the

mast.

6 Using a suitable measuring device, measure

the distance between plumb line and the face of

the number 1 mast. Refer to illustration.

Result: The distance between the plumb line

and the face of the number 1 mast does not

exceed 66.9 inches / 1700 mm. The wear pads

are in good condition.

Result: The distance between the plumb line

and the face of the number 1 mast exceeds

66.9 inches / 1700 mm. The wear pads are not

in good condition. Install new wear pads. Refer

to Repair Procedure 4-1,

How to Remove the

Mast Assembly.

b

a