Section 3 • Scheduled Maintenance Procedures

3 - 26

GR-20J • GR-26J

Part No. 227656

September 2016

Checklist D Procedure

D-1

Replace the Hydraulic Tank

Return Filter

Genie specifications require that this procedure be

performed every 1000 hours or annually,

whichever comes first.

Replacement of the hydraulic tank return filter is

essential for good machine performance and

service life. A dirty or clogged filter may cause the

machine to perform poorly and continued use may

cause component damage. Extremely dirty

conditions may require that the filter be replaced

more often.

Beware of hot oil. Contact with hot

oil may cause severe burns.

Note: Perform this procedure on a firm, level

surface.

1 Turn the key switch to off position and push in

the red Emergency Stop button to the off

position at both the ground and platform

controls.

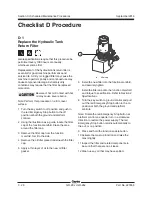

2 Using the illustration as a guide, locate the filter

cap of the function manifold. Clean the area

around the filter cap.

3 Remove the filter cap from the function

manifold. Set it to the side.

4 Remove the oil filter placed underneath the filter

cap.

5 Apply a thin layer of oil to the new oil filter

gasket.

a

filter cap

6 Install the new filter into the function manifold,

and securely tighten.

7 Install the filter cap onto the function manifold

and torque to specification. Refer to Section 2,

Specifications

.

8 Turn the key switch to ground control and pull

out the red Emergency Stop button to the on

position at both the ground and platform

controls.

Note: Rotate the red Emergency Stop button at

platform control one quarter turn in a clockwise

direction to restore the power supply. The red

Emergency Stop button returns automatically to

the out, or on position.

9 Press and hold the function enable button.

10 Activate the mast up function and raise the

mast slightly.

11 Inspect the filter and related components to

be sure that there are no oil leaks.

12 Clean up any oil that may have spilled.

a