Section 4 • Repair Procedures

4 - 8

GR-20J • GR-26J

Part No. 227656

September 2016

2-2

Platform Overload System

How to Calibrate the Platform

Overload System (if equipped)

Calibration of the platform overload system is

essential to safe machine operation. Continued

use of an improperly calibrated platform overload

system could result in the system failing to sense

an overloaded platform. The stability of the

machine is compromised and it could tip over.

Note: Perform this procedure with the machine on

a firm, level surface that is free of obstructions, and

the machine in stowed position.

1 Block the wheels at the steer end of the

machine.

2 Remove all weight, tools and accessories from

the platform.

Note: Failure to remove all weight, tools and

accessories from the platform will result in an

incorrect calibration.

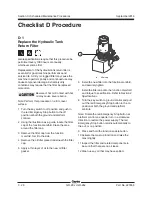

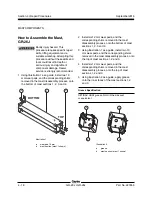

3 Fully tighten the adjusting screws of both the

overload sensors. Do not over tighten.

4 Using a suitable lifting device, place a

440 lbs / 200 Kg test weight in the center of the

platform. Secure the weight to the platform.

5 Tighten the overload spring adjustment

screw just until the screw and lock nut will

rotate freely, and the clearance between the

lock nut and sensor mounting bracket is

minimal.

a

adjusting screw

b

overload sensor number 1

c

overload spring adjustment screw

d

overload sensor number 2

e

overload sensor mounting bracket

f

overload spring

g

spacer

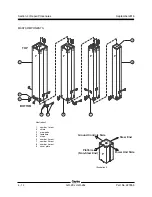

6 Place an additional 44 lbs / 20 kg test weight in

the center of the platform. Secure the weight to

the platform.

7 Turn the key switch to platform control and pull

out the red Emergency Stop button to the on

position at both the ground and platform

controls.

Note: Rotate the red Emergency Stop button at

platform control one quarter turn in a clockwise

direction to restore the power supply. The red

Emergency Stop button returns automatically to

the out, or on position.

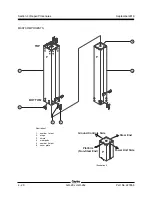

a

b

c

d

a

e

f

g

e

PLATFORM COMPONENTS