May 2022

Service and Repair Manual

Ground Controls

Part No. 1306516GT

GS

™

-2669 RT • GS

™

-3369 RT • GS

™

-4069 RT

49

How to De ter mine the R evision Lev el

How to Determine the Revision

Level

1 Turn the key switch to ground control and pull

out the red Emergency Stop button to the on

position at both ground and platform controls.

Result: The revision level of the ECM will

appear in the LED display window.

How to Adju st th e Stowe d Driv e Spee d

How to Adjust the Stowed Drive

Speed

Tip-over hazard. Do not adjust

the lift and/or drive speed higher

than specified in this procedure.

Setting drive speed greater than

specifications could cause the

machine to tip over resulting in

death or serious injury.

1 Pull out the red Emergency stop button to the

on position at the platform controls.

2 Push in the ground controls red Emergency

Stop button to the off position.

3 Turn the key switch to ground controls.

4 Press and hold both the blue platform up and

yellow platform down buttons. Pull out the red

Emergency Stop button to the on position at

the ground controls.

Result: TUNE SPEEDS is showing in the

diagnostic display window. The ECM is now in

programming mode.

5 Press the lift function enable button.

6 Use the yellow platform down arrow to scroll

to max fwd high speed drive.

Result: MAX FWD HIGH SPEED drive is

showing in the diagnostic display window.

7 Press the lift function enable button.

8 Press the yellow platform down button to

decrease the drive speed or press the blue

platform up button to increase the drive

speed. Refer to Specifications,

Performance

Specifications.

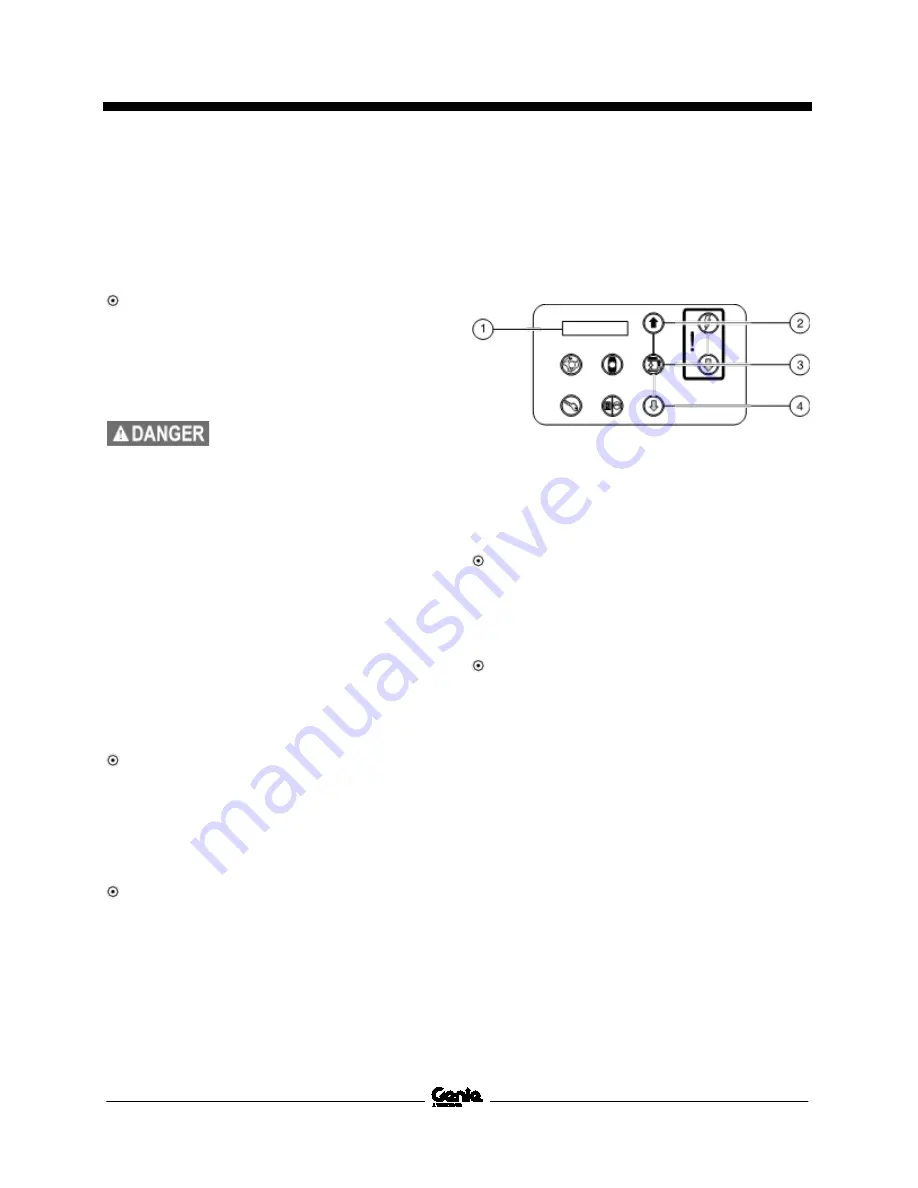

1 diagnostic display

2 blue platform up button

3 lift function enable button

4 yellow platform down button

9 Press the lift function enable button.

Result: TUNE SPEEDS is showing in the

diagnostic display window. The ECM is now in

programming mode.

10 Use the yellow platform down arrow to scroll

to max rev high speed drive.

Result: MAX REV HIGH SPEED drive is

showing in the diagnostic display window.

11 Press the lift function enable button.

12 Press the yellow platform down button to

decrease the drive speed or press the blue

platform up button to increase the drive

speed. Refer to Specifications,

Performance

Specifications.

13 Press the lift function enable button.

14 Push in the ground controls red Emergency

Stop button to the off position.

15 Check the stowed drive speed of the

machine. Refer to the Maintenance

procedure,

Test the Drive Speed - Stowed

Position.

Summary of Contents for GS-2669 IC

Page 141: ...May 2022 Service and Repair Manual 127 GM 998L Engine Wire Harness...

Page 144: ...Service and Repair Manual May 2022 130 Control Panel Circuit Diagram...

Page 145: ...May 2022 Service and Repair Manual 131 Electrical Schematic GS 69 RT GM 998L Models ANSI CSA...

Page 148: ...Service and Repair Manual May 2022 134 Electrical Schematic GS 69 RT GM 998L Models ANSI CSA...

Page 149: ...May 2022 Service and Repair Manual 135 Electrical Schematic GS 69 RT GM 998L Models ANSI CSA...

Page 152: ...Service and Repair Manual May 2022 138 Electrical Schematic GS 69 RT Diesel Models ANSI CSA...

Page 153: ...May 2022 Service and Repair Manual 139 Electrical Schematic GS 69 RT Diesel Models ANSI CSA...

Page 156: ...Service and Repair Manual May 2022 142 Electrical Schematic GS 69 RT Diesel Models ANSI CSA...

Page 157: ...May 2022 Service and Repair Manual 143 Electrical Schematic GS 69 RT GM 998L Models AS CE...

Page 160: ...Service and Repair Manual May 2022 146 Electrical Schematic GS 69 RT GM 998L Models AS CE...

Page 161: ...May 2022 Service and Repair Manual 147 Electrical Schematic GS 69 RT GM 998L Models AS CE...

Page 164: ...Service and Repair Manual May 2022 150 Electrical Schematic GS 69 RT Diesel Models AS CE...

Page 165: ...May 2022 Service and Repair Manual 151 Electrical Schematic GS 69 RT Diesel Models AS CE...

Page 168: ...Service and Repair Manual May 2022 154 Electrical Schematic GS 69 RT Diesel Models AS CE...

Page 169: ...May 2022 Service and Repair Manual 155 Hydraulic Schematic GS 69 RT...

Page 171: ......