Section 3 • Scheduled Maintenance Procedures

November 2014

Part No. 229753

GS-2669 RT • GS-3369 RT • GS-4069 RT

3 - 17

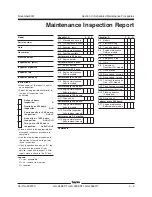

CHECKLIST

B

PROCEDURES

9 Check the ambient air temperature and adjust

the specific gravity reading for each cell as

follows:

•

Add 0.004 to the reading of each cell for

every 10° F / 5.5° C above 80° F / 26.7° C.

•

Subtract 0.004 from the reading of each cell for

every 10° F / 5.5° C below 80° F / 26.7° C.

Result: All battery cells display a specific

gravity of 1.277 +/- 0.007. The battery is fully

charged. Proceed to step 10.

Result: One or more battery cells display a

specific gravity from 1.269 to 1.218. The battery

is still usable, but at a lower performance so will

need to be recharged more often. Proceed to

step 11.

Result: One or more battery cells display a

specific gravity from 1.217 to 1.173. The battery

is approaching the end of its life. Proceed to

step 11.

Result: The difference in specific gravity

readings between cells is greater than 0.1 OR

the specific gravity of one or more cells is 1.172

or less. Replace the battery.

10 Check the battery acid level. If needed,

replenish with distilled water to

1

/

8

inch / 3 mm

below the bottom of the battery fill tube. Do not

overfill.

11 Install the vent caps and neutralize any

electrolyte that may have spilled.

B-2

Inspect the Electrical Wiring

Genie requires that this procedure be performed

every 250 hours or quarterly, whichever comes

first.

Maintaining electrical wiring in good condition is

essential to safe operation and good machine

performance. Failure to find and replace burnt,

chafed, corroded or pinched wires could result in

unsafe operating conditions and may cause

component damage.

Electrocution/burn hazard. Contact

with hot or live circuits may

result in death or serious injury.

Remove all rings, watches and

other jewelry.

1 Inspect the following areas for burnt, chafed,

corroded and loose wires:

• Ground control panel

• Hydraulic tray

• Engine tray

• Scissor arms

• Platform controls

Summary of Contents for GS-2669 RT

Page 169: ...Section 6 Schematics November2014 6 9 Control Panel Circuit Diagram 6 10 ...

Page 235: ...Section 6 Schematics November2014 6 75 6 76 Electrical Schematic GS 4069 RT Gas LPG Models AS ...

Page 238: ...November2014 Section 6 Schematics 6 78 Electrical Schematic GS 4069 RT Gas LPG Models AS 6 77 ...

Page 243: ...Section 6 Schematics November2014 6 83 Electrical Schematic GS 4069 RT Diesel Models AS 6 82 ...

Page 246: ...November2014 Section 6 Schematics 6 86 Electrical Schematic GS 4069 RT Diesel Models AS 6 85 ...

Page 251: ...Section 6 Schematics November2014 6 91 Electrical Schematic GS 4069 RT Gas LPG Models CE 6 92 ...

Page 254: ...November2014 Section 6 Schematics 6 94 Electrical Schematic GS 4069 RT Gas LPG Models CE 6 93 ...

Page 259: ...Section 6 Schematics November2014 6 99 6 100 Electrical Schematic GS 4069 RT Diesel Models CE ...

Page 267: ...Section 6 Schematics November2014 6 107 Hydraulic Schematic GS 2669 RT and GS 3369 RT 6 108 ...

Page 270: ...November2014 Section 6 Schematics 6 110 Hydraulic Schematic GS 4069 RT 6 109 ...