Section 4 • Repair Procedures

November 2014

4 - 18

GS-2669 RT • GS-3369 RT • GS-4069 RT

Part No. 229753

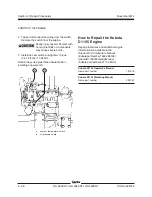

32 Tag and disconnect the harness from the lower

lift cylinder valve block.

33 Tag and disconnect the hydraulic hoses from

the lower lift cylinder. Plug the hoses and cap

the fittings.

Bodily injury hazard. Spraying

hydraulic oil can penetrate and

burn skin. Loosen hydraulic

connections very slowly to allow

the oil pressure to dissipate

gradually. Do not allow oil to squirt

or spray.

34 Remove the hose clamps and hoses from the

number 1 inner arm.

35 Using an overhead lifting device attach a 4 hook

sling chain to the ends of the number 1 inner

arm (index #14). Make the chains tight but do

not apply lifting pressure.

Crushing hazard. The linkage

assembly could become

unbalanced and fall if not properly

supported when removed from the

machine.

36 Remove the two carriage bolts that secure the

inner arm and chassis pivot to the steer end of

the drive chassis.

37 Move the linkage towards the non-steer end of

the machine until the slider feet are clear of the

slider channel.

38 Carefully lift the linkage assembly off of the

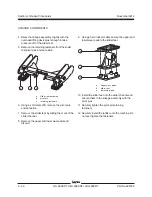

machine and place it on a structure capable of

supporting it.

Separate the link sets:

1 Using an overhead lifting device attach a 4 hook

sling chain to the ends of the inner arm (index

#5, #9, #14, #17 or #26). Make the chains tight

but do not apply lifting pressure.

Crushing hazard. The linkage

assembly could become

unbalanced and fall if not properly

supported when removed from the

machine.

2 Remove the retaining fasteners from the center

pivot pins (index #2, #4, #7, #11 or #13).

Note: Do not remove the external snap ring.

3 Using a soft metal drift, remove the center pivot

pins and set aside.

4 Carefully lift and separate the linkage assembly

apart and place it on a structure capable of

supporting it. It will need to be carefully

adjusted for proper balancing.

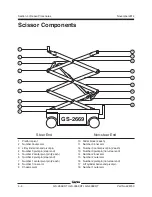

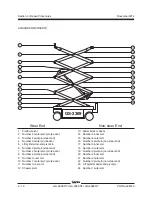

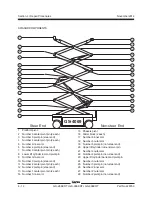

SCISSOR COMPONENTS

Summary of Contents for GS-2669 RT

Page 169: ...Section 6 Schematics November2014 6 9 Control Panel Circuit Diagram 6 10 ...

Page 235: ...Section 6 Schematics November2014 6 75 6 76 Electrical Schematic GS 4069 RT Gas LPG Models AS ...

Page 238: ...November2014 Section 6 Schematics 6 78 Electrical Schematic GS 4069 RT Gas LPG Models AS 6 77 ...

Page 243: ...Section 6 Schematics November2014 6 83 Electrical Schematic GS 4069 RT Diesel Models AS 6 82 ...

Page 246: ...November2014 Section 6 Schematics 6 86 Electrical Schematic GS 4069 RT Diesel Models AS 6 85 ...

Page 251: ...Section 6 Schematics November2014 6 91 Electrical Schematic GS 4069 RT Gas LPG Models CE 6 92 ...

Page 254: ...November2014 Section 6 Schematics 6 94 Electrical Schematic GS 4069 RT Gas LPG Models CE 6 93 ...

Page 259: ...Section 6 Schematics November2014 6 99 6 100 Electrical Schematic GS 4069 RT Diesel Models CE ...

Page 267: ...Section 6 Schematics November2014 6 107 Hydraulic Schematic GS 2669 RT and GS 3369 RT 6 108 ...

Page 270: ...November2014 Section 6 Schematics 6 110 Hydraulic Schematic GS 4069 RT 6 109 ...