Section 4 • Repair Procedures

November 2014

4 - 38

GS-2669 RT • GS-3369 RT • GS-4069 RT

Part No. 229753

b

c

d

a

7-3

Software Configuration

How to Configure the Software

The Electronic Control Module (ECM) contains

programming for all configurations of the GS-69.

Machines can be adjusted to a different

configuration using the buttons at the ground

controls. To determine the software revision level,

see 7-2,

How to Determine the Revision Level

.

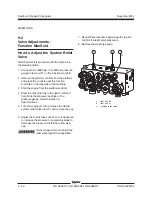

ANSI and CSA models:

1 Turn the key switch to ground controls and pull

out the red Emergency Stop buttons to the on

position at both platform and ground controls.

Result: The revision level of the ECM will

appear in the LED display window. Note the

result.

2 Push in the red Emergency Stop button to the

off position at the ground controls.

3 Press and hold both the blue platform up and

yellow platform down buttons. Pull out the red

Emergency Stop button to the on position at the

ground controls.

Result:

TUNE

SPEEDS

is showing in the diagnostic

display window.

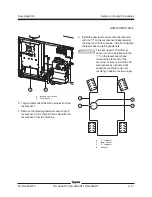

a

diagnostic display

b

blue platform up button

c

lift function enable button

d

yellow platform down button

Machine Option Definitions

Descent Delay:

This option halts descent when

the down limit switch is activated. All controls

must be released for 4 to 6 seconds before

descent is re-enabled. Required for Europe.

Motion Alarm:

The motion alarm will sound

when activating a function.

Motion Beacons:

The flashing beacons

operate only when activating a function.

Overload:

This cuts out all functions when the

platform overload pressure switch is tripped.

The red Emergency Stop button must be

cycled before any function can be resumed.

Required for Europe and Australia.

Beacons:

When installed on the machine, the

flashing beacons operate continuously when

the key switch is turned to ground or platform

controls and both red Emergency Stop buttons

are pulled out to the on position.

Generator:

When installed on the machine, the

generator can only be operated when the

engine is running.

Sim Operation:

Not available.

Outriggers:

When installed on the machine,

the outrigger option must be enabled.

GROUND CONTROLS

Summary of Contents for GS-2669 RT

Page 169: ...Section 6 Schematics November2014 6 9 Control Panel Circuit Diagram 6 10 ...

Page 235: ...Section 6 Schematics November2014 6 75 6 76 Electrical Schematic GS 4069 RT Gas LPG Models AS ...

Page 238: ...November2014 Section 6 Schematics 6 78 Electrical Schematic GS 4069 RT Gas LPG Models AS 6 77 ...

Page 243: ...Section 6 Schematics November2014 6 83 Electrical Schematic GS 4069 RT Diesel Models AS 6 82 ...

Page 246: ...November2014 Section 6 Schematics 6 86 Electrical Schematic GS 4069 RT Diesel Models AS 6 85 ...

Page 251: ...Section 6 Schematics November2014 6 91 Electrical Schematic GS 4069 RT Gas LPG Models CE 6 92 ...

Page 254: ...November2014 Section 6 Schematics 6 94 Electrical Schematic GS 4069 RT Gas LPG Models CE 6 93 ...

Page 259: ...Section 6 Schematics November2014 6 99 6 100 Electrical Schematic GS 4069 RT Diesel Models CE ...

Page 267: ...Section 6 Schematics November2014 6 107 Hydraulic Schematic GS 2669 RT and GS 3369 RT 6 108 ...

Page 270: ...November2014 Section 6 Schematics 6 110 Hydraulic Schematic GS 4069 RT 6 109 ...