Operator's Manual

First Edition • First Printing

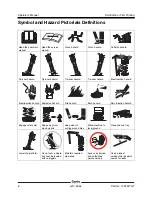

Work Area Safety

18 GS

™

-4655

Part No. 1294977GT

Battery Safety

Burn Hazards

Batteries contain acid.

Always wear protective

clothing and eye wear when

working with batteries.

Avoid spilling or contacting

battery acid. Neutralize

battery acid spills with baking

soda and water.

Do not expose the batteries or the charger to water

or rain during charging.

Explosion Hazards

Keep sparks, flames, and

lighted tobacco away from

batteries. Batteries emit

explosive gas.

The battery tray should

remain open during the

entire charging cycle.

Do not contact the battery

terminals or the cable

clamps with tools that may

cause sparks.

Component Damage Hazard

Do not use any battery charger greater than 24V to

charge the batteries.

Electrocution/Burn Hazards

Connect the battery charger to a

grounded, AC 3-wire electrical

outlet only.

Inspect daily for damaged cords,

cables and wires. Replace

damaged items before operating.

Avoid electrical shock from contact with battery

terminals. Remove all rings, watches and other

jewelry.

Tip-over Hazard

Do not use batteries that weigh less than the

original equipment. Batteries are used as

counterweight and are critical to machine stability.

Each battery must weigh 37 kg. Battery tray

including batteries must weigh a minimum of

188 kg.

Lifting Hazard

Use the appropriate number of people and proper

lifting techniques when lifting batteries.

Summary of Contents for GS-4655

Page 54: ......