October 2015

Second Edition - First Printing

Part No.

57.0009.0662

GTH-1256 47

Maintenance

Check the Engine Coolant Level -

Liquid Cooled Models

Maintaining the engine coolant at the proper level

is essential to engine service life. Improper coolant

level will affect the engine’s cooling capability and

damage engine components. Daily checks will

allow the inspector to identify changes in coolant

level that might indicate cooling system problems.

1 Visually inspect the sight gauge located on the

top side of the radiator.

Result: The fluid level should be halfway in the

sight gauge.

Bodily Injury Hazard. Fluids in the radiator

are under pressure and extremely hot. Use

caution when removing cap and adding fluids.

Check the Tire Pressure

Tip-over hazard. An over-inflated tire can

explode which may compromise machine

stability and cause the machine to tip over.

Tip-over hazard. The use of temporary flat tire

repair products may lead to tire failure which

could compromise machine stability and cause

the machine to tip over.

Bodily injury hazard. An over-inflated tire can

explode and may cause death or serious

injury.

Note: This procedure does not need to be

performed on machines equipped with foam-filled

tires.

1 Check each tire with an air pressure gauge.

Add air as needed.

Tire pressure

87 psi

6 bar

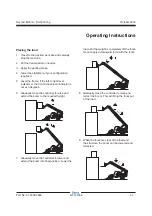

Check Mirrors and RODS System

Maintaining the indirect visual aids is essential to

workplace visibility.

1. Visually inspect all mirrors, the camera lens

and monitor screen of the RODS system (if

equipped) to ensure they are working properly and

clean and free from debris.