October 2015

Second Edition - First Printing

Part No.

57.0009.0662

GTH-1256 5

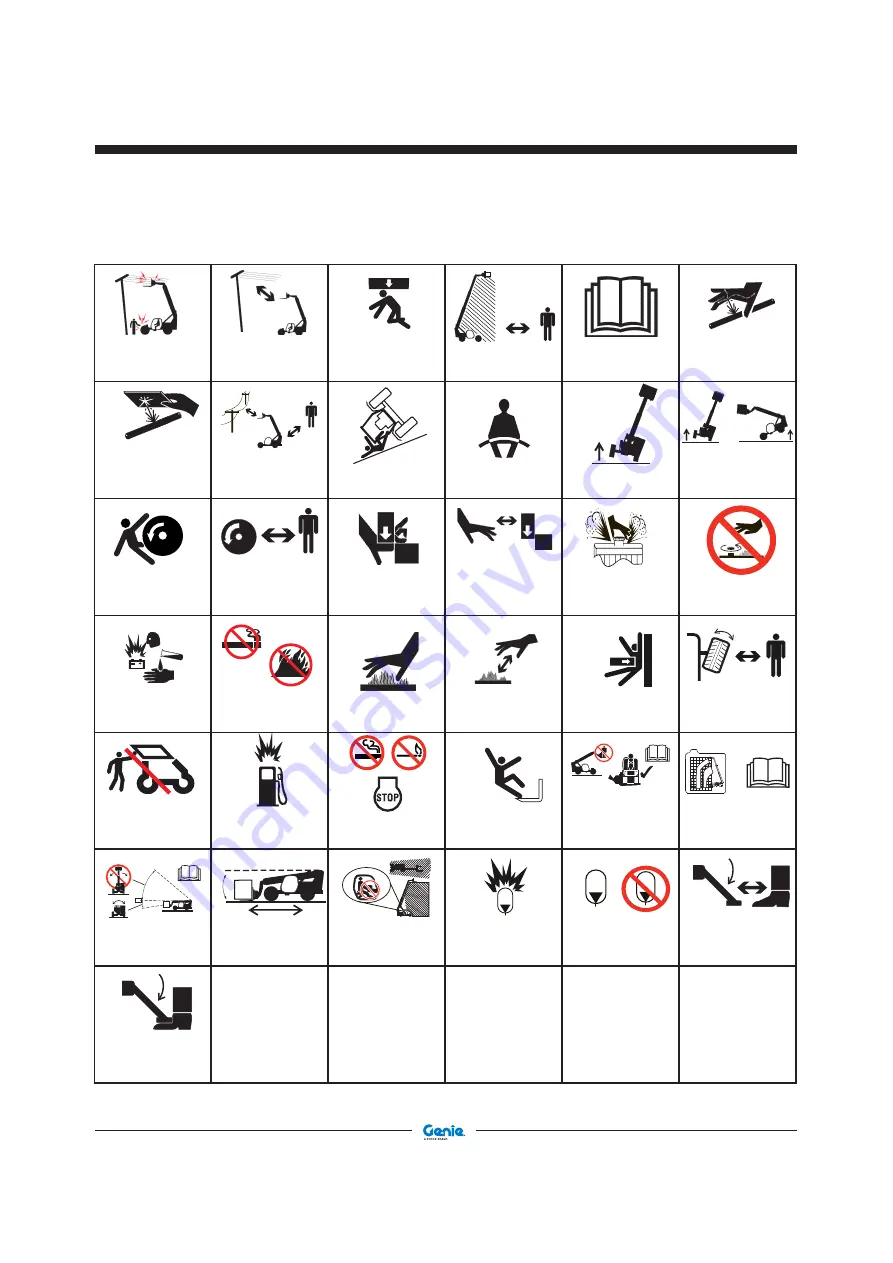

Symbol and Hazard Pictorials De

fi

nitions

Maintain required

clearance.

Read the operator's

manual.

Burn Hazard

Explosion/burn

hazard

No smoking.

No open flame.

Allow surfaces to

cool.

Crush Hazard

Keep clear of

moving parts.

Allow engine

compartment

access

Electrocution

hazard

Refer to load charts

and manual

Tip-over hazard

Always wear seat

belt.

Keep load low

Crush hazard.

Crush hazard.

Work platform use

Crush hazard

Keep away from

moving parts

Burn hazard.

Do not loosen cap

until cool.

Keep away from

moving parts.

Explosion hazard

o

2

N

2

Use nitrogen.

Not use oxygen.

No people under

load

Injection hazard

Use a piece of

cardboard or paper

to search for leaks

Maintain required

clearance.

Crush hazard.

Tip-over hazard

Explosion/burn

hazard

Fall hazard

Sway operation

Crush hazard.

Keep away from

stabilizers.

No smoking. No

open flame.

No people under

load