August 2018

Part No. 57.4400.9220GT

GTH-2506 GTH-3007

3-7

Section 3 • Scheduled Maintenance Procedures

CHECKLIST A PROCEDURES

A-4

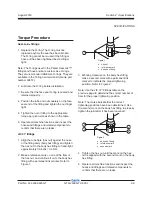

Lubricate the Boom

Genie specifications require that this procedure

be performed every 8 hours or daily, whichever

comes first.

Greasing the specified locations is essential for

good machine performance and service life.

Operating the machine with little or no grease

may cause the machine to perform poorly and

continued use may cause component damage.

1 Fully extend and raise the boom, then retract

the boom, checking to insure it operates

smoothly. There should be a light film of

lubricant on wear pad contact surfaces.

Result: Boom operates smoothly and a thin film

of lubricant is visible. Proceed to step 4.

Result: Boom does not extend or retract

smoothly and no lubricant is visible on wear

pad contact surfaces. Proceed to step 2.

2 Apply a thin layer of grease to the underside

of the number 2 boom tube where it makes

contact with the number 1 boom tube lower

wear pads.

3 Lubricate the top and side boom tube wear

pads.

4 Return the boom to the stowed position.

Grease Specification

MASCHERPA GR 529 GREASE

Genie part number

09.4693.0007

A-5

Perform Engine Maintenance

Engine specifications require that this procedure

be performed every 8 hours or daily, whichever

comes first.

Deutz TD 2.9 L4

Lubricating oil level - check/add

Coolant level - check/add

Visual inspection

Suction air filter/dry air filter - check

Fuel pre-filter - check/empty water

Only for Deutz TD 2.9 L4 - Stage IIIB

Exhaust system including exhaust

aftertreatment components - check for leaks

Required maintenance procedures and additional

engine information is available in the

Deutz TD 2.9 L4 Operation and Maintenance

Manual

(Deutz part number 0312 3893).

Deutz TD 2.9 L4 Operation and Maintenance

Manual

Genie part number

57.4700.0006