3-12

GTH-2506 GTH-3007

Part No. 57.4400.9220GT

August 2018

Section 3 • Scheduled Maintenance Procedures

B-2

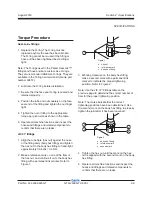

Check the Exhaust System

Genie requires that this procedure be performed

every 250 hours or quarterly, whichever comes

first.

Maintaining the exhaust system is essential

to good engine performance and service life.

Running the engine with a damaged or leaking

exhaust system can cause component damage

and unsafe operating conditions.

WARNING

Bodily injury hazard. Do not

inspect while the engine is

running. Remove the key to

secure from operation.

CAUTION

Bodily injury hazard. Beware of

hot engine components. Contact

with hot engine components may

cause severe burns.

1 Open the engine access cover.

2 Be sure that the fastener is tight.

3 Inspect all welds for cracks.

4 Inspect for exhaust leaks - i.e., carbon buildup

around seams and joints.

5 Close the engine access cover.

B-3

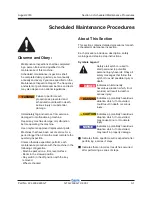

Inspect the Tires, Wheels and

Lug Nut Torque

Genie requires that the first inspection be

performed after the first 50 hours of operation.

Genie requires that this procedure be performed

every 250 hours or quarterly, whichever comes

first.

Maintaining the tires and wheels in good condition,

including proper wheel fastener torque, is essential

to safe operation and good performance. Tire and/

or wheel failure could result in a machine tip-over.

Component damage may also result if problems

are not discovered and repaired in a timely

fashion.

WARNING

Bodily injury hazard. An

overinflated tire can explode and

could result in death or serious

injury.

WARNING

Tip over hazard. Do not use

temporary flat tire repair

products.

The tires on some machines are foam filled and do

not need air added to them.

1 Check all tire treads and sidewalls for cuts,

cracks, punctures and unusual wear.

2 Check each wheel for damage, bends and

cracks.

3 Check each lug nut for proper torque. Refer to

Section 2,

Specifications

.

4 Check the air pressure in each tire. Refer to

Section 2,

Specifications

.

CHECKLIST B PROCEDURES