August 2018

Part No. 57.4400.9220GT

GTH-2506 GTH-3007

4-39

Section 4 • Repair Procedures

8-1

LMI

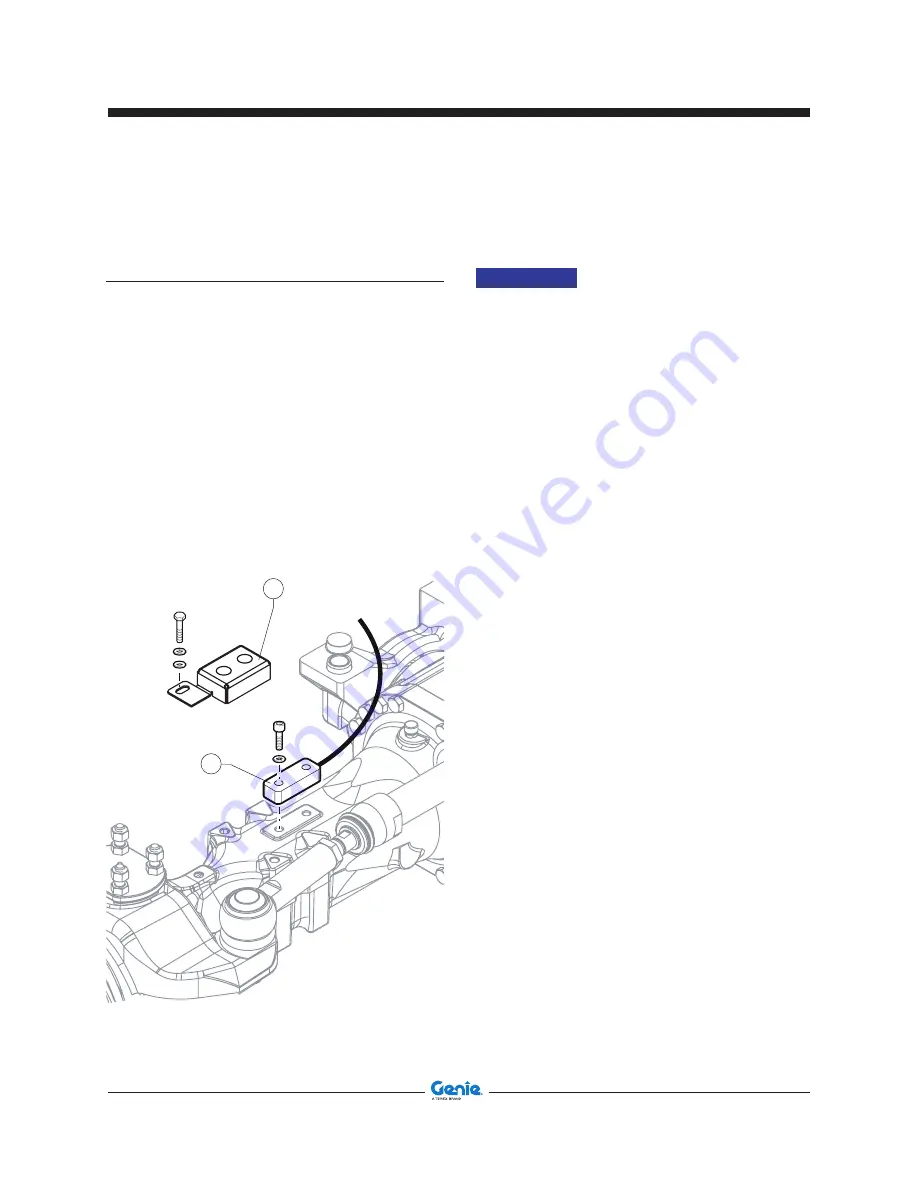

How to Remove a Load Cell

1 Go to the back of the machine. The load cell "b"

is installed on the axle near the right wheel.

2 Remove the retaining fasteners that secure

guard "a". Remove the guard.

3 Disconnect the harness from the load cell.

4 Remove the retaining fasteners that secure the

load cell. Remove the load cell.

How to Install the Load Cell

NOTICE

The extensometer and the axle

must be stored at a similar

temperature before the mounting

operation. The time is linked

to the thermal inertia of both

pieces (extensometer: 1 hour for

ΔT

=20°C).

1 The extensometer must be mounted without

any strain on the axle.

2 Place the extensometer with the 2 screws M10

(should be easy to tight the screws by hands):

to improve the tightening force applied by

the screws and to prevent any loosening, we

recommend to use Loctite 242.

3 The tightening operation of the 2 M10 screws

should be done progressively:

- Tightening of screw n.1 at torque T1=40 Nm

- Tightening of screw n.2 at torque T1=40 Nm

- Tightening of screw n.1 then screw n.2 at

torque T2=65 Nm.

4 Nominal torque : T= 65 Nm ± 5% for M10

screws quality 12.9 with lubrication due to the

LOCTITE glue before polymerisation (μ=0,15

and F ~ 3500 daN).

Time of polymerization of the glue: 1 hour at

ambient temperature before using.

Instructions before calibration procedure

1 Make a mechanical running in (preloading the

axle) before calibration of the extensometer

with the display.

2 This mechanical running in consists in making

the axle work to a level of strain equivalent to 3

times the nominal level of strain in the axle for

the full range in static.

LMI (Overload System)

a

b