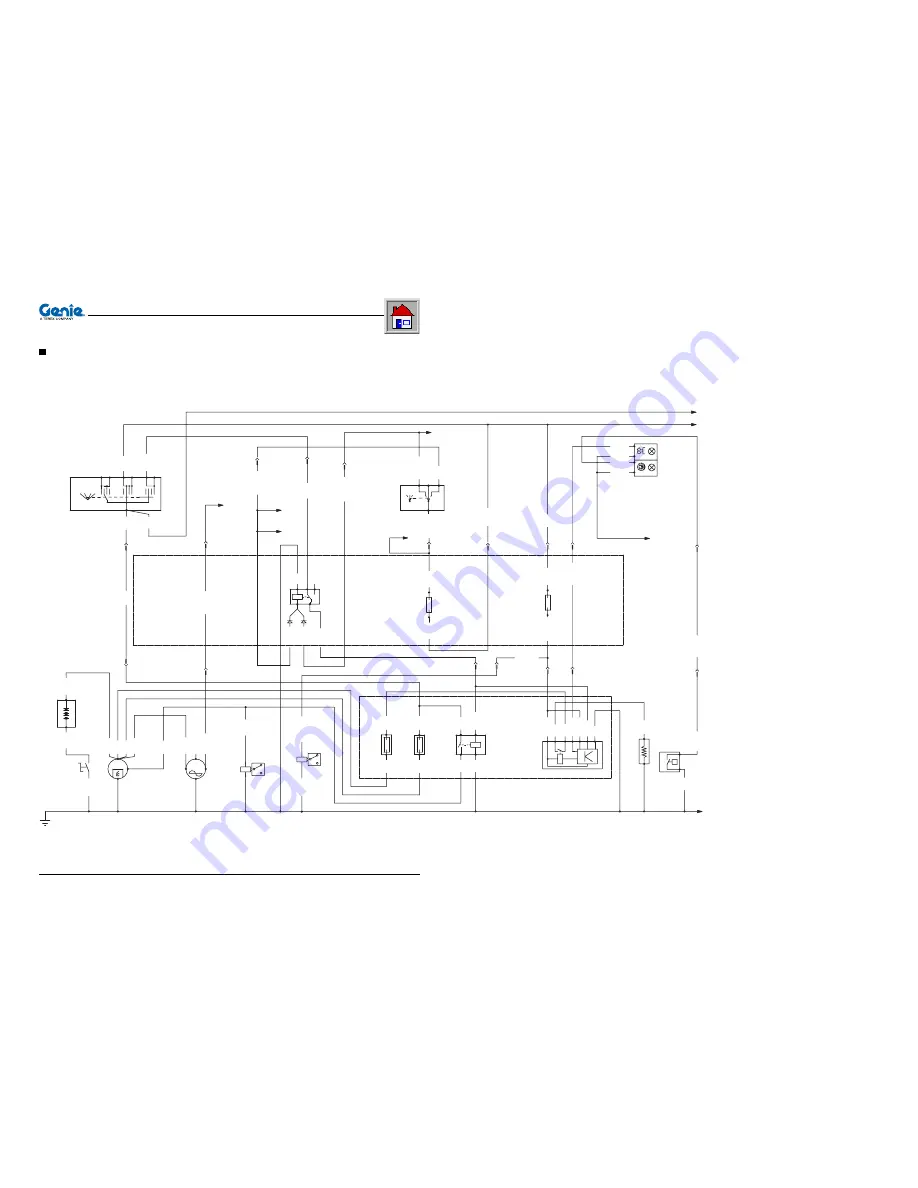

Document 57.0005.8200 - 12/2005

Handler with telescopic boom

GTH-6622

Page

G-7

TABLES AND DOCUMENTS ENCLOSED

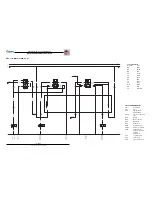

G-3.2 WIRING DIAGRAM tab. 1/8

LIST OF ABBREVIATIONS

Label

Description

F##

Fuses

H##

Lamps, lights,

warning lights

HA##

Clacson or back-up

horn

K##

Relays

M##

Motor or pump

P##

Indicators

R##

Resistance

RP##

Potentiometers

SW##

Switches, selectors

SS##

Sensors, micro-

switches, pressure

switches,

transducers

Y##

Solenoid valves

X##

Connectors

A##

Other components

COLOUR TABLE

Acronym

Colour

BK

Black

BN

Brown

RD

Red

OG

Orange

YE

Yellow

GN

Green

BU

Blue

VT

Purple

GY

Grey

WH

White

PK

Pink

TQ

Light blue

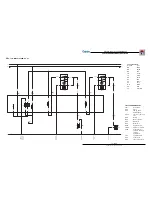

SOLENOID V

A

LV

E

ENGINE STOP

ENGINE ST

AR

T

RELA

Y

8/C5

OG/GNø1

OG/GNø1.5

2/F5

87A 87

85

86

BUø1.5

30

K02

BKø1

X5

4

VTø1.5

OG/GNø1

BN/BKø1

CHANGE OVER

SWITCH

4

OGø1

3

F

N

R

F

N

+

PK/BKø1.5

1

R

BN/BKø1.5

3

BNø2.5

F13

PKø1.5

5A

X3

2/C7

PKø1.5

SW03

BNø2.5

X5

OG/GNø1.5

2/C7

1

2

X3

BN/BKø1.5

BU/RDø1

RDø6

BKø50

WH/RDø1.5

24

X2

VT/WHø1.5

P

WH/RDø1

BNø4

4/E8

BU/RDø1

BKø1

SS09

6

X2

GY/BUø1

GY/BUø1

X3

12

RD/BKø1

GY/BUø1

A02

R01

K11

F30

F31

RD/BKø1

H01

Y03

M02

M01

SW2

A01

SW01

CUT

-OFF

4/E2

31

2/A10

2/G10

2/G10

30

15

F5

RESIST

ANCE

GLOW PLUGS

12V BA

TTER

Y

16

X3

X2

23

X3

18

25

X2

VT/WHø1

RD/BKø1

7

X3

5A

WH/RDø1.5

BNø2.5

X2

15

WHø6

L

VT/WHø1

WHø6

WHø6

WH/RDø1

87

86

30

BKø1

BUø1.5

T

50

85

RDø50

RDø6

50A

WHø6

50A

BNø6

BNø6

87 85

30 86

BUø1.5

RDø4

BKø1

BUø4

X2

27

15

30

VTø1.5

BNø4

RDø4

RDø6

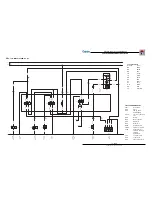

ACC 0

ST

IGN

ACC

BAT

IGN

ST

X3

1

A

X1

ADDICTIONAL FUEL

SOLENOID V

A

LV

E

AL

TERNA

TOR

MOTOR

BUø2.5

RDø10

BU/RDø1

B+

W

D+

BUø4

RDø10

ST

AR

TER

BNø6

BNø6

M

BKø50

RDø50

-

+

KEY SWITCH

IGNITION

Y07

WH/RDø1.5

BKø1.5

BA

TTER

Y

PREHEA

TING

GLOW PLUGS

AIR FIL

TER

W

ARNING LIGHT

PROTECTION

SYSTEM

CONTROL UNIT

PREHEA

TING

MAXIFUSE

FUSE

RELA

Y

ST

AR

TING

CONTROL UNIT

PREHEA

TING

AIR FIL

TER

CLOGGING

SENSOR

X3

7