Document 57.0005.8200 - 12/2005

Handler with telescopic boom

GTH-6622

Page

D-4

MAINTENANCE

Every 500 working hours or every six months

Jobs to be done in addition to those above.

1

Visually check the smoke quantity evacuated from

the engine exhaust

2

Check the tightening of the engine fixing screws

3

Check the tightening of the cab fixing screws

4

Check the backlash between pins and bushings

in all joints

5

Change the hydraulic oil filter of the transmission

6

Change the hydraulic oil filter in the tank

7

Have the hydraulic system checked by a skilled

technician

8

Change the main cartridge of the engine air filter

9

Clean or replace, if nececessary, the air filter in the

cab

Every 1000 working hours or yearly

Jobs to be done in addition to those above

1

Change the oil in the front and rear differential units

and in the power divider

2

Change the oil in the four wheel reduction gears

3

Change the hydraulic oil

4

Change the safety cartridge of the engine air filter

■

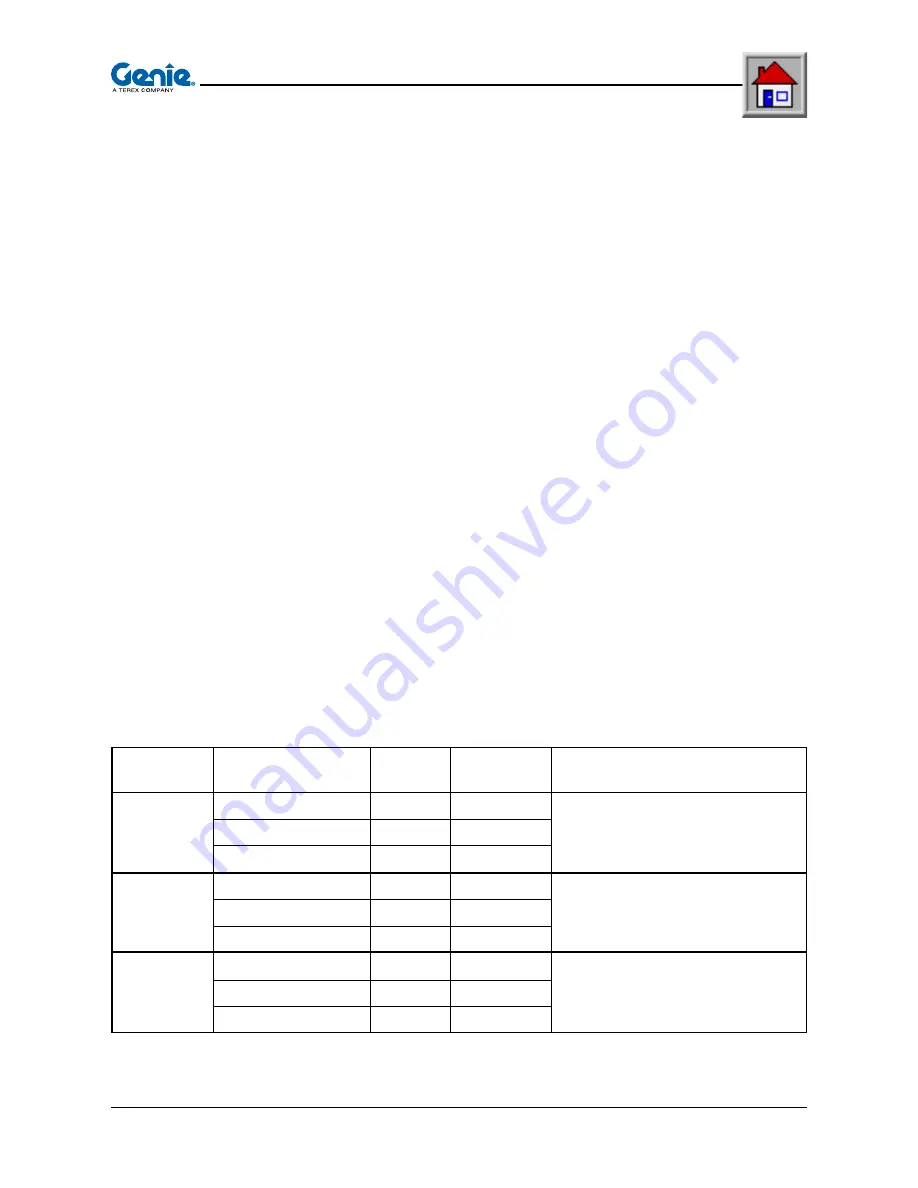

D-2.1

OIL CHANGE SCHEDULE

Job

operating

service

Oil type

hours*

interval*

Oil level check

10

daily

SHELL RIMULA 15W-40

First change

50

-

Subsequent changes

250

monthly

Oil level check

250

monthly

FUCHS TITAN GEAR LS 85 W-90

First change

-

-

API GL-5 LS / GL-5

Subsequent changes

1000

yearly

Oil level check

250

monthly

SHELL TELLUS T 46

Subsequent changes

1000

yearly

DENISON HF-1, DIN 51524

part 3 Cat. HV

Engine

Axles and

power

divider

Hydraulic

oil

* whichever occurs first