Section 3 • Scheduled Maintenance Procedures

September 2016

3 - 2

GRC

Part No. 227123

SCHEDULED MAINTENANCE PROCEDURES

Maintenance Symbols Legend

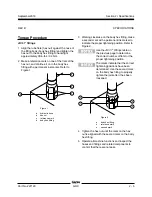

Note: The following symbols have been used in

this manual to help communicate the intent of the

instructions. When one or more of the symbols

appears at the beginning of a maintenance

procedure, it conveys the meaning below.

Indicates that tools will be required to

perform this procedure.

Indicates that new parts will be required

to perform this procedure.

Indicates that a cold motor or pump will

be required to perform this procedure.

Indicates that dealer service will be

required to perform this procedure.

Pre-delivery Preparation Report

The pre-delivery preparation report contains

checklists for each type of scheduled inspection.

Make copies of the

Pre-delivery Preparation

report

to use for each inspection. Store completed forms

as required.

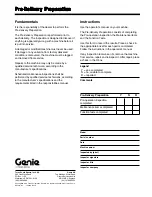

Maintenance Schedule

There are five types of maintenance inspections

that must be performed according to a schedule—

daily, quarterly, semi-annually, annually, and

two year. The

Scheduled Maintenance Procedures

Section and the Maintenance Inspection Report

have been divided into five subsections—A, B, C,

D, and E. Use the following chart to determine

which group(s) of procedures are required to

perform a scheduled inspection.

Inspection

Checklist

Daily or every 8 hours

A

Quarterly or every 250 hours

A + B

Semi-annually or every 500 hours

A + B + C

Annually or every 1000 hours

A + B + C + D

Two year or every 2000 hours

A + B + C + D + E

Maintenance Inspection Report

The maintenance inspection report contains

checklists for each type of scheduled inspection.

Make copies of the

Maintenance Inspection Report

to use for each inspection. Maintain completed

forms for a minimum of 4 years or in compliance

with employer, jobsite and governmental

regulations and requirements.