Part No. 1268494

S-100 • S-105 • S-120 • S-125

3 - 85

March 2017

Section 3 • Repair Procedures

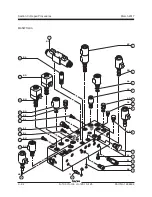

MANIFOLDS

10-3

Valve Adjustments - Function

Manifold, S-100 and S-105 Models

How to Adjust the Function

Manifold Relief Valve

Note: Perform this procedure with the boom in the

stowed position.

1 Connect a 0 to 5000 psi / 0 to 345 bar pressure

gauge to the test port on the function manifold.

2 Start the engine from the ground controls.

3 Simultaneously push and hold the function

enable/high speed button and the boom

retract button with the boom fully retracted.

Observe the pressure reading on the pressure

gauge. Refer to Specifications,

Hydraulic Oil

Specifications.

4 Turn the engine off. Use a wrench to hold the

relief valve and remove the cap (item FI).

5 Adjust the internal hex socket. Turn it clockwise

to increase the pressure or counterclockwise to

decrease the pressure. Install the relief valve

cap.

Tip-over hazard. Do not adjust

the relief valve higher than

specified.

6 Repeat steps 2 through 5 to confirm the relief

valve pressure.

How to Adjust the Boom Extend

Relief Valve

Note: Perform this procedure with the boom in the

stowed position.

1 Connect a 0 to 3000 psi / 0 to 207 bar pressure

gauge to the test port on the function manifold.

2 Start the engine from the ground controls.

3 Fully raise and extend the boom.

4 Simultaneously push and hold the function

enable/high speed button and the boom

extend button with the boom fully extended.

Observe the pressure reading on the pressure

gauge. Refer to Specifications,

Hydraulic

Specifications.

5 Turn the engine off. Use a wrench to hold the

relief valve and remove the cap (item FA).

6 Adjust the internal hex socket. Turn it clockwise

to increase the pressure or counterclockwise to

decrease the pressure. Install the relief valve

cap.

Tip-over hazard. Do not adjust

the relief valve higher than

specified.

7 Repeat steps 2 through 6 to confirm the relief

valve pressure.

Summary of Contents for S-100

Page 246: ...March 2017 Section 6 Schematics 6 22 Safety Circuit Schematic 6 21 ...

Page 259: ...Section 6 Schematics March 2017 6 35 6 36 Electrical Schematic Generator Options ...

Page 262: ...March 2017 Section 6 Schematics 6 38 6 37 Electrical Schematic 12 kW Generator welder option ...

Page 264: ...March 2017 Section 6 Schematics 6 40 Perkins 1104D 44T Engine Electrical Schematic 6 39 ...

Page 265: ...Section 6 Schematics March 2017 6 41 Perkins 854F 34T Engine Electrical Schematic 6 42 ...

Page 268: ...March 2017 Section 6 Schematics 6 44 Perkins 854F 34T Engine Harness 6 45 ...

Page 269: ...Section 6 Schematics March 2017 6 45 Deutz TD2011L04i Engine Electrical Schematic 6 46 ...

Page 271: ...Section 6 Schematics March 2017 6 47 Deutz TD2 9 Engine Electrical Schematic 6 48 ...

Page 274: ...March 2017 Section 6 Schematics 6 50 Deutz TD2 9 Engine Electrical Harness 6 51 ...

Page 276: ...March 2017 Section 6 Schematics 6 52 6 53 Hydraulic Schematic 12 kW Generator welder option ...