3 - 136

S-100 • S-105 • S-120 • S-125

Part No. 1268494

March 2017

Section 3 • Repair Procedures

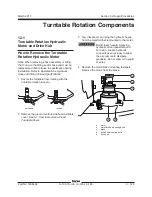

3 Mark the mounting position of the steer sensor

cover on the yoke.

Note: It is very important that the steer sensor

is installed in the exact position it was in prior

to removal. If the steer sensor is not installed

correctly, the steer function may operate

improperly. If any steer functions operate

improperly after removing and installing a steer

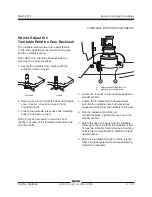

sensor, see 13-1,

How to Adjust a Steer Sensor.

4 Remove the steer sensor cover retaining

fasteners. Carefully remove the steer sensor

cover and lay it out of the way.

Component damage hazard. The

steer sensor is a very sensitive

instrument. It can be damaged

internally if it is dropped or

sustains any physical shock, even

if the damage is not visible.

5 Lay the hoses and steer sensor cable out of the

way.

Component damage hazard.

Cables and hoses can be

damaged if they are kinked or

pinched.

6 Mark the mounting position of the steer sensor

activator pin mounted to the top of the yoke

pivot pin.

7 Remove the steer sensor activator pin retaining

fasteners. Remove the steer sensor activator

pin from the machine.

Note: It is very important that the steer sensor

activator pin is installed in the exact position it was

in prior to removal. If the steer sensor activator pin

is not installed correctly, the steer function may

operate improperly. If any steer functions operate

improperly after removing and installing a steer

sensor activator pin, see 13-1,

How to Adjust a

Steer Sensor.

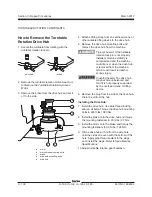

8 Loosen the wheel lug nuts. Do not remove

them.

9 Center a lifting jack of ample capacity under the

axle of the yoke and drive hub to be removed.

Do not raise the machine.

10 Block the wheels at the opposite end of the

machine.

11 Raise the machine approximately 6 inches

(15 cm) and place blocks under the chassis for

support.

12 Remove the lug nuts and remove the tire and

wheel assembly.

13 Remove the drive motor mounting fasteners.

14 Slide the drive motor shaft out of the drive hub

and remove the drive motor from the machine.

15 Remove the pin retaining fasteners from the

steering cylinder rod-end pivot pins. Remove

the pins.

16 Remove the pin retaining fasteners from the

upper and lower yoke pivot pins.

AXLE COMPONENTS

Summary of Contents for S-100

Page 246: ...March 2017 Section 6 Schematics 6 22 Safety Circuit Schematic 6 21 ...

Page 259: ...Section 6 Schematics March 2017 6 35 6 36 Electrical Schematic Generator Options ...

Page 262: ...March 2017 Section 6 Schematics 6 38 6 37 Electrical Schematic 12 kW Generator welder option ...

Page 264: ...March 2017 Section 6 Schematics 6 40 Perkins 1104D 44T Engine Electrical Schematic 6 39 ...

Page 265: ...Section 6 Schematics March 2017 6 41 Perkins 854F 34T Engine Electrical Schematic 6 42 ...

Page 268: ...March 2017 Section 6 Schematics 6 44 Perkins 854F 34T Engine Harness 6 45 ...

Page 269: ...Section 6 Schematics March 2017 6 45 Deutz TD2011L04i Engine Electrical Schematic 6 46 ...

Page 271: ...Section 6 Schematics March 2017 6 47 Deutz TD2 9 Engine Electrical Schematic 6 48 ...

Page 274: ...March 2017 Section 6 Schematics 6 50 Deutz TD2 9 Engine Electrical Harness 6 51 ...

Page 276: ...March 2017 Section 6 Schematics 6 52 6 53 Hydraulic Schematic 12 kW Generator welder option ...