3 - 14

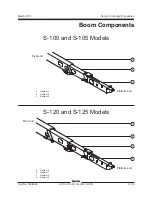

S-100 • S-105 • S-120 • S-125

Part No. 1268494

March 2017

Section 3 • Repair Procedures

Function speeds:

Note: Be sure the machine is in the stowed

position and the boom is rotated between the circle

end tires.

Note: Perform this procedure with the machine

parked on a firm, level surface which is free of

obstructions.

12 Start the engine from the platform controls.

13 Select a boom function that needs the function

speed set.

14

Boom up/down functions:

Starting in the

stowed position, move the joystick full stroke

in the up direction. When the alarm sounds,

move the joystick in the opposite direction full

stroke until the alarm sounds again. Return the

joystick to center.

Boom extend/retract functions:

Raise the

boom until the low-speed drive function is

enabled. Move the joystick full stroke in the

extend direction. When the alarm sounds,

move the joystick in the opposite direction full

stroke until the alarm sounds again. Return the

joystick to center.

Turntable rotate functions:

Raise the boom

until the low-speed drive function is enabled.

Move the joystick full stroke to the left (cw) until

the drive enable light turns on. Then move the

joystick full stroke to the right (ccw). When the

alarm sounds, move the joystick in the opposite

direction full stroke until the alarm sounds

again. Return the joystick to center.

15 Once all the joystick controllers have been

calibrated, push in the red Emergency Stop

button at the platform controls to save the

settings in memory.

Note: The red Emergency Stop button at the

platform controls must be pushed in to the off

position following calibration of the joystick

controllers to save the settings in memory.

16 At the ground controls, turn the key switch to

the off position, wait a moment and then turn

the key switch to platform controls.

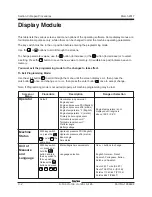

17 Check the display at the ground controls to be

sure there are no calibration faults.

Note: There should be no calibration faults shown

on the display. If calibration faults exist, repeat this

procedure.

How to Adjust the Function

Speeds

1 Pull out the red Emergency Stop button to the

on position at both the ground and platform

controls.

PLATFORM CONTROLS

REV B

7 While holding the joystick in position, press the

engine start button

at the platform controls

to set the joystick controller threshold.

8 Repeat steps 3 through 7 for each joystick

controlled machine function (boom up/down

and turntable rotate left/right, boom extend/

retract, and drive forward/reverse).

9 Once all the joystick controllers have been

calibrated, push in the Emergency Stop button

at the platform controls to save the settings in

memory.

Note: The red Emergency Stop button at the

platform controls must be pushed in to the off

position following calibration of the joystick

controllers to save the settings in memory.

10 At the ground controls, turn the key switch to

the off position, wait a moment and then turn

the key switch to platform controls.

11 Check the display at the ground controls to be

sure there are no calibration faults.

Note: There should be no calibration faults shown

on the display. If calibration faults exist, repeat this

procedure.

Summary of Contents for S-100

Page 246: ...March 2017 Section 6 Schematics 6 22 Safety Circuit Schematic 6 21 ...

Page 259: ...Section 6 Schematics March 2017 6 35 6 36 Electrical Schematic Generator Options ...

Page 262: ...March 2017 Section 6 Schematics 6 38 6 37 Electrical Schematic 12 kW Generator welder option ...

Page 264: ...March 2017 Section 6 Schematics 6 40 Perkins 1104D 44T Engine Electrical Schematic 6 39 ...

Page 265: ...Section 6 Schematics March 2017 6 41 Perkins 854F 34T Engine Electrical Schematic 6 42 ...

Page 268: ...March 2017 Section 6 Schematics 6 44 Perkins 854F 34T Engine Harness 6 45 ...

Page 269: ...Section 6 Schematics March 2017 6 45 Deutz TD2011L04i Engine Electrical Schematic 6 46 ...

Page 271: ...Section 6 Schematics March 2017 6 47 Deutz TD2 9 Engine Electrical Schematic 6 48 ...

Page 274: ...March 2017 Section 6 Schematics 6 50 Deutz TD2 9 Engine Electrical Harness 6 51 ...

Page 276: ...March 2017 Section 6 Schematics 6 52 6 53 Hydraulic Schematic 12 kW Generator welder option ...