Part No. 1268494

S-100 • S-105 • S-120 • S-125

3 - 15

March 2017

Section 3 • Repair Procedures

PLATFORM CONTROLS

Specifications

Ramp rate (factory settings)

Turntable rotate

accelerate

2 seconds

decelerate

0.25 second

Primary boom up/down

accelerate

3 seconds

decelerate

0..25 second

Primary boom extend/retract

accelerate

2 seconds

decelerate

0.25 second

Jib boom up/down

accelerate

2 seconds

decelerate

0.25 second

Drive

accelerate

2 seconds

REV B

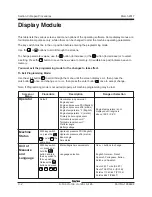

2 Press and hold the enter button

on the

ground control panel while turning the key

switch to ground controls. Hold the enter

button for approximately 5 seconds.

3 Press the plus button

twice, then press the

minus button

twice.

4 Press the scroll button until the function to

be adjusted is displayed.

5 Press the plus button

to increase the speed

or press the minus button

to decrease the

speed.

6 Press the enter button

to save the setting in

memory.

7 Push one of the LCD

screen buttons shown

until

exit

is displayed.

8 Press the plus

button to select

yes

and then

press the enter button

.

9 Continue to perform this procedure until the

machine function speed meets specification.

Refer to

Specifications

for function speeds.

How to Adjust the Function

Ramp Rate Setting

The ramp rate setting of a joystick controls the time

at which it takes for the joystick to reach maximum

output, when moved out of the neutral position.

The ramp rate settings of a joystick can be

changed to compensate for hydraulic pump wear

to maintain peak performance from the machine.

Note: Perform this procedure with the boom in the

stowed position.

1 Pull out the red Emergency Stop button to the

on position at both the ground and platform

controls.

2 Press and hold the enter button

on the

ground control panel while turning the key

switch to ground controls. Hold the enter

button for approximately 5 seconds.

3 Press the plus button

twice, then press the

scroll button twice.

4 Press the scroll button until the function to

be adjusted is displayed.

5 Press the plus button

to increase the ramp

rate or press the minus button

to decrease

the ramp rate.

6 Press the enter button

to save the setting in

memory.

7 Push one of the LCD screen buttons shown

until

exit

is displayed.

8 Press the plus

button to select

yes

and

then press the enter button

.

Summary of Contents for S-100

Page 246: ...March 2017 Section 6 Schematics 6 22 Safety Circuit Schematic 6 21 ...

Page 259: ...Section 6 Schematics March 2017 6 35 6 36 Electrical Schematic Generator Options ...

Page 262: ...March 2017 Section 6 Schematics 6 38 6 37 Electrical Schematic 12 kW Generator welder option ...

Page 264: ...March 2017 Section 6 Schematics 6 40 Perkins 1104D 44T Engine Electrical Schematic 6 39 ...

Page 265: ...Section 6 Schematics March 2017 6 41 Perkins 854F 34T Engine Electrical Schematic 6 42 ...

Page 268: ...March 2017 Section 6 Schematics 6 44 Perkins 854F 34T Engine Harness 6 45 ...

Page 269: ...Section 6 Schematics March 2017 6 45 Deutz TD2011L04i Engine Electrical Schematic 6 46 ...

Page 271: ...Section 6 Schematics March 2017 6 47 Deutz TD2 9 Engine Electrical Schematic 6 48 ...

Page 274: ...March 2017 Section 6 Schematics 6 50 Deutz TD2 9 Engine Electrical Harness 6 51 ...

Page 276: ...March 2017 Section 6 Schematics 6 52 6 53 Hydraulic Schematic 12 kW Generator welder option ...