3 - 30

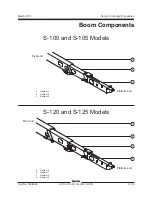

S-100 • S-105 • S-120 • S-125

Part No. 1268494

March 2017

Section 3 • Repair Procedures

4-1

Cable Track

The cable track and boom cable tube guides

cables and hoses running up the boom. The

cable track can be repaired link by link without

removing the cables and hoses that run through

it. Removing the entire cable track assembly may

be necessary when performing major repairs that

involve removing the boom.

How to Remove the Boom

Cable Track

Note: When removing a hose assembly or fitting,

the O-ring on the fitting and/or hose end must be

replaced and then torqued to specification during

installation.

Refer to Specifications,

Hydraulic Hose and Fitting

Torque Specifications.

Note: Perform this procedure with the boom fully

stowed.

1 Remove the hose and cable cover retaining

fasteners from the jib boom leveling arm.

Remove the hose and cable cover from the

machine.

2 Remove the protective coil sleeve from the

hose and cable bundle at the platform end of

the boom cable tube.

3 Tag, disconnect and plug all hydraulic hoses

from the boom cable tube to the platform

manifold.

Note: If your machine is equipped with an airline

to platform option and/or weld cable option, the

airline and/or cable must be disconnected from the

platform before the cable track is removed.

4 Tag and disconnect the black electrical

connector from the bottom of the control box.

5 Remove the platform-end boom cable tube

mounting fasteners at the engine side of the

machine.

6 Remove the cable track mounting fasteners

from the cable track support at the engine side

of the machine.

7 Remove the wear pad mounting weldment from

the cable track support bracket at the engine

side of the machine.

8 Remove the hose and cable clamp from the

cable track support bracket at the engine side

of the machine.

9 Place blocks between the cable track and the

boom cable tube for support.

10 Strap together the boom cable tube, blocks of

wood, and the cable track at the engine side of

the machine.

Component damage hazard.

Cables, hoses, boom cable tube

and cable track can be damaged if

they are kinked or pinched.

11 Remove the limit switch cover retaining

fasteners from the top of the number 2 boom

tube at the platform end of the machine.

Remove the limit switch cover.

12 Tag and disconnect the wiring connectors from

the proximity and limit switches on top of the

number 2 boom tube at the platform end of the

machine.

BOOM COMPONENTS

Summary of Contents for S-100

Page 246: ...March 2017 Section 6 Schematics 6 22 Safety Circuit Schematic 6 21 ...

Page 259: ...Section 6 Schematics March 2017 6 35 6 36 Electrical Schematic Generator Options ...

Page 262: ...March 2017 Section 6 Schematics 6 38 6 37 Electrical Schematic 12 kW Generator welder option ...

Page 264: ...March 2017 Section 6 Schematics 6 40 Perkins 1104D 44T Engine Electrical Schematic 6 39 ...

Page 265: ...Section 6 Schematics March 2017 6 41 Perkins 854F 34T Engine Electrical Schematic 6 42 ...

Page 268: ...March 2017 Section 6 Schematics 6 44 Perkins 854F 34T Engine Harness 6 45 ...

Page 269: ...Section 6 Schematics March 2017 6 45 Deutz TD2011L04i Engine Electrical Schematic 6 46 ...

Page 271: ...Section 6 Schematics March 2017 6 47 Deutz TD2 9 Engine Electrical Schematic 6 48 ...

Page 274: ...March 2017 Section 6 Schematics 6 50 Deutz TD2 9 Engine Electrical Harness 6 51 ...

Page 276: ...March 2017 Section 6 Schematics 6 52 6 53 Hydraulic Schematic 12 kW Generator welder option ...