Summary of Contents for S-40 TRAX

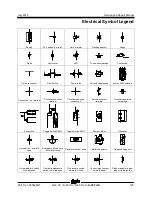

Page 144: ...Service and Repair Manual July 2019 134 Electrical Schematic TCON ...

Page 147: ...July 2019 Service and Repair Manual 137 Electrical Schematic PCON ...

Page 148: ...Service and Repair Manual July 2019 138 Electrical Schematic Deutz 2 9 Models ...

Page 150: ...Service and Repair Manual July 2019 140 S 40 XC S 45 XC S 40 TraX S 45 TraX Part No 1286829GT ...

Page 152: ...Service and Repair Manual July 2019 142 Electrical Schematic Deutz 2011 Models ...

Page 153: ...July 2019 Service and Repair Manual 143 Electrical Schematic Perkins 404F Models ...

Page 156: ...Service and Repair Manual July 2019 146 Electrical Schematics Ford MSG425 Models ...

Page 159: ......