September 2015

Service and Repair Manual

Specifications

Part No. 1268515

Z-34/22 Bi-Energy

9

Torque Pr ocedure

Torque Procedure

Seal-Lok™ fittings

1 Replace the O-ring. The O-ring must be

replaced anytime the seal has been broken.

The O-ring cannot be re-used if the fitting or

hose end has been tightened beyond finger

tight.

Note: The O-ring in Parker Seal Lok™ fittings and

hose end are custom-size O-rings. They are not

standard size O-rings. They are available in the

O-ring field service kit (Genie part number 49612).

2 Lubricate the O-ring before installation.

3 Be sure the O-ring face seal is seated and

retained properly.

4 Position the tube and nut squarely on the face

seal end of the fitting, and tighten the nut

finger tight.

5 Tighten the nut or fitting to the appropriate

torque. Refer to the appropriate torque chart

in this section.

6 Operate all machine functions and inspect the

hose, fittings and related components to

confirm there are no leaks.

JIC 37° fittings

1 Align the tube flare (hex nut) against the nose

of the fitting body (body hex fitting) and tighten

the hex nut to the body hex fitting to hand

tight, approximately 30 in-lbs / 3.4 Nm.

2 Using a permanent ink marker, make a

reference mark on one the flats of the hex nut

and continue the mark onto the body of the

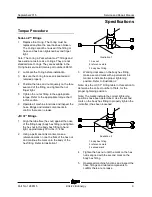

hex fitting. Refer to Illustration 1.

Illustration 1

1 hex nut

2 reference mark

3 body hex fitting

3 Working clockwise on the body hex fitting,

make a second mark with a permanent ink

marker to indicate the proper tightening

position. Refer to Illustration 2.

Note: Use the JIC 37° Fitting table in this section to

determine the correct number of flats, for the

proper tightening position.

Note: The marks indicate the correct tightening

positions have been determined. Use the second

mark on the body hex fitting to properly tighten the

joint after it has been loosened.

Illustration 2

1 body hex fitting

2 reference mark

3 second mark

4 Tighten the hex nut until the mark on the hex

nut is aligned with the second mark on the

body hex fitting.

5 Operate all machine functions and inspect the

hose, fittings and related components to

confirm there are no leaks.

Summary of Contents for Z-22 Bi-Energy

Page 63: ...September 2015 Service and Repair Manual Manifolds Part No 1268515 Z 34 22 Bi Energy 51...

Page 99: ...September 2015 Service and Repair Manual 87 Electrical Schematic from serial number 5427 CE...

Page 102: ...Service and Repair Manual September 2015 90 Electrical Schematic from serial number 5427 CE...

Page 103: ...September 2015 Service and Repair Manual 91 Ground Control Box Switch Panel Wiring Diagram...

Page 106: ...Service and Repair Manual September 2015 94 Ground Control Box Terminal Strip Wiring Diagram...

Page 107: ...September 2015 Service and Repair Manual 95 Platform Control Box Wiring Diagram...

Page 110: ...Service and Repair Manual September 2015 98 Power Cable Wiring Diagram...

Page 111: ...September 2015 Service and Repair Manual 99 Drive Contactor Panel Wiring Diagram...

Page 114: ...Service and Repair Manual September 2015 102 Manifold and Limit Switch Wiring Diagram...

Page 119: ...September 2015 Service and Repair Manual 107 Engine Wiring Diagram...

Page 123: ......