3 - 16

Z-30/20N • Z-30/20N RJ • Z-34/22 • Z-34/22N

Part No. 139378

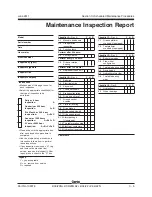

Section 3 • Scheduled Maintenance Procedures

June 2011

REV B

CHECKLIST

B

PROCEDURES

B-10

Test the Drive Speed -

Stowed Position

Note: Genie specifications require that this

procedure be performed every 250 hours or

quarterly, whichever comes first.

Proper drive function movement is essential to

safe machine operation. The drive function should

respond quickly and smoothly to operator control.

Drive performance should also be free of

hesitation, jerking and unusual noise over the

entire proportionally controlled speed range.

1 Select a test area that is firm, level and free of

obstructions.

2 Create start and finish lines by marking two

lines on the ground 40 feet / 12.2 m apart.

3 Turn the key switch to platform control and pull

out the red Emergency Stop button to the on

position at both the ground and platform

controls.

4 Choose a reference point on the machine; i.e.,

contact patch of a tire, as a visual reference for

use when crossing the start and finish lines.

5 Bring the machine to maximum drive speed

before reaching the start line. Begin timing

when your reference point on the machine

crosses the start line.

6 Continue at full speed and note the time when

your machine reference point passes over the

finish line. Refer to Section 2,

Specifications.

B-11

Test the Drive Speed -

Raised or Extended Position

Note: Genie specifications require that this

procedure be performed every 250 hours or

quarterly, whichever comes first.

Proper drive function movement is essential to

safe machine operation. The drive function should

respond quickly and smoothly to operator control.

Drive performance should also be free of

hesitation, jerking and unusual noise over the

entire proportionally controlled speed range.

1 Select a test area that is firm, level and free of

obstructions.

2 Create start and finish lines by marking two

lines on the ground 40 feet / 12.2 m apart.

3 Raise the primary boom more than

5 feet / 1.5 m.

4 Choose a reference point on the machine; i.e.,

contact patch of a tire, as a visual reference for

use when crossing the start and finish lines.

5 Bring the machine to maximum drive speed

before reaching the start line. Begin timing

when your reference point on the machine

crosses the start line.

6 Continue at full speed and note the time when

your machine reference point passes over the

finish line. Refer to Section 2,

Specifications.

Summary of Contents for Z-30/20N

Page 1: ......

Page 148: ...6 46 June2011 Section 6 Schematics 6 45 Power Cable Wiring Diagram...

Page 149: ...6 47 Section 6 Schematics June2011 6 48 Drive Contactor Panel Wiring Diagram...

Page 152: ...6 50 June2011 Section 6 Schematics Manifold and Limit Switch Wiring Diagram 6 49...

Page 153: ...6 51 Section 6 Schematics June2011 6 52 LVI BCI Option Wiring Diagram...

Page 156: ...6 54 June2011 Section 6 Schematics 6 53 Charger Interlock Option...

Page 157: ...6 55 Section 6 Schematics June2011 6 56 CTE Option CE Models...

Page 160: ...6 58 June2011 Section 6 Schematics Hydraulic Schematic 6 57...