5

ENGLISH

230 V~ (+6 -10%) - 50/60 Hz.

550 W

500 W

500 mA

-20°C +50°C

3

Adjustable using trimmer (from 10 to 120 sec.)

90 x 195 x 250 mm.

IP54

Power supply

Absorbed power

Max. motor load

Max. load on accessoies

Ambient temperature

Protection fuses

Operating logic

Opening /closing time

Housing degree of protection (external)

Housing dimensions (external)

Functions selected with dip-switches

Terminal board outputs

Sensor connector

Radio control connector

Terminal board inputs

Thrust force

Pause time

Automatic / Semi-automatic /

Automatic with stop / Step-step with stop

Adjustable using trimmer (from 0 to 120 sec.)

Adjustable using trimmer

Total opening / Partial opening /

Closing photocells / Opening-closing limit switch /

STOP / Mains power supply + Ground / Antenna

Radio receiver boards molex connector

Anti-crushing sensor

Accessory power supply 24 V~ / Flasher /

Gate status led / Motor

Operating modes

Closing photocell reaction

MICROPROCESSOR CONTROL UNIT FOR SLIDING GATES

USER INSTRUCTIONS - INSTALLATION STANDARDS

1. GENERAL FEATURES

Thanks to the high-power performance of its built-in microprocessor, this control unit for sliding gates offers a wide number

of services and adjustments. In addition, electronic power control guarantees a high safety level.

A sophisticated electronic control constantly monitors the power circuit and cuts off the unit when problems arise which

reduce the operating efficiency of the electronic clutch.

The main settings and operating modes can be defined using dip-switches while time and motor power adjustments are

performed using the trimmers installed on the electronic circuit board.

7 built-in LEDS constantly display the status of inputs, outputs in addition to any circuit malfunctions.

2. TECHNICAL FEATURES

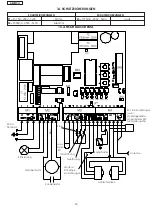

3. TERMINAL BOARD M1 (HIGH VOLTAGE) CONNECTIONS - DESCRIPTION

3.1 MAINS POWER

Terminals “1 - 2 - 3” (Live - Ground - Neutral), Power supply voltage 230 V~ 50/60 Hz.

WARNING:

the ground connection is mandatory to ensure proper unit operation.

4. TERMINAL BOARD M2 (HIGH VOLTAGE) CONNECTIONS - DESCRIPTION

4.1 FLASHER

Terminals “4 - 5” (Live - Neutral). Use a flasher with an operating voltage of 230 V~ (40W max.). When power is supplied to the

system the flasher will blink once to confirm that the unit is properly connected to the electric power supply.

4.2 GEAR UNIT

Terminals “6 - 7 - 8” (Close - Common - Open). Connect the motor and relative condenser.

WARNING:

if the gear unit is incorrectly connected or the connection is not completed, the unit will be inhibited and this

status will be indicated by diagnostic

LED 7

.

Notes:

1)

To install electric cables, us adequate rigid and/or flexible tubes.

2)

Always separate the low-voltage connection cables from the 230V~ power supply cables. Cables for the power

supply to the equipment must have a 1.5 mm

2

section. To avoid interference, us separate sheathes.

3)

The box features 4 break-through holes Ø25 where Pg16 cable clamps with minimum protection degree IP54

must be mounted (not supplied).

5. TERMINAL BOARD M3 (LOW VOLTAGE) CONNECTIONS - DESCRIPTION

5.1 GATE STATUS LED

Terminals “9-10”. The signal led constantly displays gate status and motion.

OFF

= gate closed;

ON

= gate open;

SLOW FLASHING

= gate opening;

FAST FLASHING

= gate closing.