MISTRAL

ENGLISH

Instructions for use

Page

Read the instructions carefully before using the product and

store them for future use.

The User must not in any way attempt to repair or to take direct

action and must solely contact qualified GENIUS personnel or

GENIUS service centres

.

GENERAL SAFETY REGULATIONS

If correctly installed and used, the

MISTRAL

automated system will

ensure a high degree of safety. Some simple rules on behaviour

can prevent accidental trouble:

Do not stand near the automated system, and do not allow chil-

dren, persons or things to do so, especially when it is operating.

Keep radio-controls, or any other pulse generators that could

involuntarily activate the automated system, well away from

children.

Do not allow children to play with the automated system.

Do not willingly obstruct gate movement.

Prevent any branches or shrubs from interfering with gate mo-

vement.

Keep the indicator-lights efficient and easy to see.

Do not attempt to activate the gate by hand unless you have

released it.

In the event of malfunctions, release the gate to allow access and

wait for qualified technical personnel to do the necessary work.

When you have set manual operation mode, cut power to the

system before restoring normal operation.

Do not in any way modify the components of the automated

system.

Do not attempt any kind of repair of direct action whatever and

contact qualified personnel only.

At least every six months: arrange a check by qualified personnel

of the automated system, safety devices and earth connec-

tion.

DESCRIPTION

The

MISTRAL

automated system for swing gates is an electro-

mechanical operator that transmits motion to the leaf via a worm

screw system.

The operator is available in many versions covering therefore every

installation requirement. The “LS” versions are equipped with ope-

ning and closing limit switches.

The models with non-reversing mechanics ensure mechanical

locking of the leaf when the motor is not operating. A convenient

and reliable release with customized key makes it possible to move

the leaf by hand in the event of malfunction or power failure.

The model with reversing mechanics requires the use of an electric

lock to ensure mechanical locking of the leaf.

In the event of malfunction or power failure, just release the electric

lock to move the leaf by hand. It is not equipped with a release

device.

ALWAYS make sure that the system is not powered before

releasing the electric lock with the key.

All models, if correctly installed, ensure an installation in compliance

with the current safety regulations.

Automated systems include safety devices (photocells) that pre-

vent the gate from closing when there is an obstacle in the area

they protect.

The warning-light indicates that the gate is currently moving.

MANUAL OPERATION

The reversible models has no release device. To move the

leaf by hand, just release the electric lock.

Before releasing the electric lock always make sure that the

system is not powered.

If the automated system needs to be moved manually due to a

power lack or to an operator malfunction, proceed as follows:

Cut power by means of the safety circuit breaker (even in the

event of a power lack).

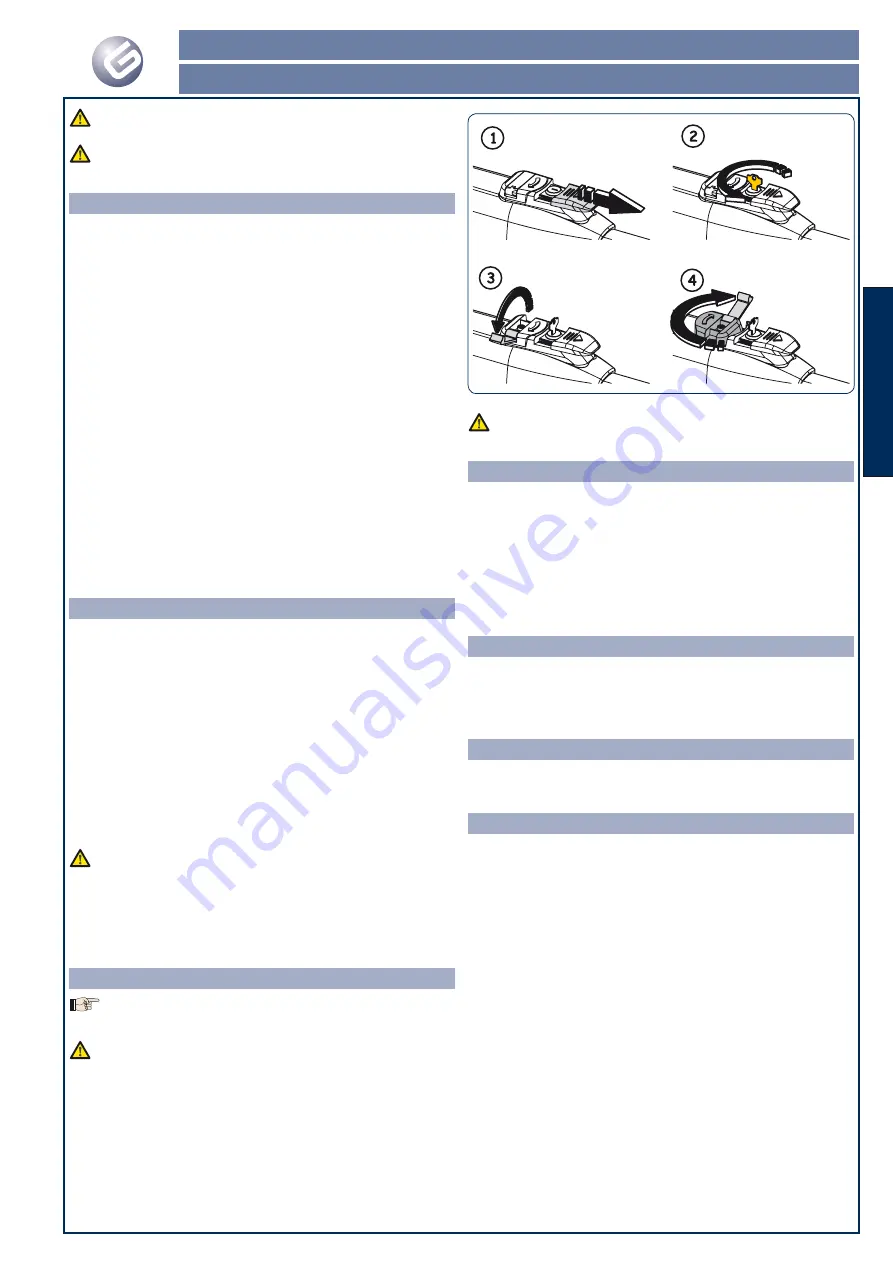

Slide the protective cap, Fig. 1 -

a

.

Insert the key and turn it 90°, Fig. 1 -

b

.

Lift the control lever, Fig. 1 -

c

.

To release the operator turn 180° the control lever to the direc-

tion indicated by the arrow on the release system, Fig. 1 -

d

.

Open and close the leaf manually.

•

•

•

•

•

•

•

•

•

•

•

•

1.

2.

3.

4.

5.

6.

To hold the operator in manual operation the release device

should be left in its current positions and the system should

be without power.

RESTORING NORMAL OPERATION

To restore normal operating conditions, proceed as follows:

Make sure that the system is not powered.

Turn the release system 180° in the opposite direction of the

arrow.

Turn 90° the release key and remove it.

Close the control lever and the protection cover.

Make sure that the gate cannot be moved manually.

Power up the system and perform some movements in order

to check the correct restoring of every function of the auto-

mated system.

MAINTENANCE

In order to ensure correct operation and constant safety over time,

make a general check of the system every six months, paying

special attention to the safety devices. In the booklet “User gui-

de”, a form has been prepared for the recording of maintenance

operations.

REPAIRS

The User must not in any way attempt to repair or to take direct

action and must solely contact qualified GENIUS personnel or

GENIUS service centres.

AVAILABLE ACCESSORIES

For accessories, see the GENIUS catalogue.

1.

2.

3.

4.

5.

6.

Fig. 1

Fig. 1