11

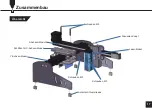

Machine Debugging and Optimization

①

If engraved lines appear as jagged, please lower the travel speed (also known as feed rate), and repeat the test until the pattern is

normal. We suggest starting with a feed rate of no more than 1000 and working down from there until you get results that suit your

needs.

②

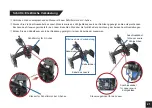

If shapes like circles and squares appear to come out deformed, start by trying to lower your travel speed and if the results do not

improve, check the tension of your belts on the X and Y axis. If a belt is too loose, or too tight it can cause undesirable results. If

you need to adjust the belt tension, please see the following instructions:

-

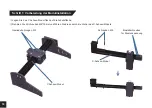

Loosen the tightness adjusting screw of the X-axis synchronous

belt and move the cover shell to adjust the tightness of the X-axis

synchronous belt.

-

Loosen the tightening adjusting screw of Y axis synchronous belt,

and move the tightening adjusting screw of Y axis synchronous

belt to adjust the tightness of Y axis synchronous belt.

- Pay attention to ensure smooth movement of the machine in both

X and Y axes after tensioning the X and Y axis synchronous belts.

For best results try to make the tensions of each axis as equal as

possible.

③

Take care when working with clear or reflective materials such as

acrylic or some metals. The laser will go straight through clear

surfaces and engrave the area underneath and reflective surfaces

can damage the laser. In order to engrave these materials you will

need to cover with a layer of paint or something like painters tape.

Depending on the material, you can use the black pen included

in the package for this purpose.

Cover Shell

Y Axis Belt Tension

Adjustment Buckle

Belt Tension

Adjustment Screws