73

MANUALE ISTRUZIONI

Rev. 01_05_2018

Serie Clinic 3

INNOVATIVE CLEAN TECHNOLOGY

ETHAFILTER s.r.l.

Via Dell’Artigianato, 16/18

I-36050 Sovizzo (Vicenza) Italia

Tel. + 39 / 0444 376402

Fax +39 / 0444 376415

e-mail: ethafilter@ethafilter.com

CERTIFICATE of CONFORMITY

STERILE FILTER ELEMENT

Model: EDT 5635SR

These aseptic class filter elements are produced to the highest quality standards to ensure the requirements of sterile

degree in compressed air and gas feed.

Materials of construction are as follows:

Endcaps:

AISI 304 grade stainless steel or FDA allowed white sintetic material

Inner and outer cylinder:

expanded AISI 304 grade stainless steel

High Efficiency Filtration layer:

"depth sandwich" of borosilicate glass micro fibre

Sealant:

white silicone compound, selected for resistance to high temperature,

composition in accordance with F.D.A. recommendations.

O-ring:

high temperature silicone compound, composition in accordance with F.D.A.

recommendations.

The high efficiency filter media is made of certified HEPA grade borosilicate glass microfibre, having a penetration of

less than 0.0001% at 0.3

μ

., equivalent to an overall efficiency

≥

0.3

μ

when tested with a DOP aerosol and measured

with a nucleus condensate particle counter.

Sealant remains flexible when warming-up, in order to compensate for metal parts expansion during sterilisation.

N.B.:

It is User's responsibility to ensure that a suitable process for inhibiting growth of trapped bacteria and virus is respected. It

is therefore recommended to sterilise the filter prior commencement of each sequence of aseptic duty. These elements are

capable of withstanding sterilisation phases of 20 ÷ 30 minutes in autoclave at 120 °C (50 steps maximum executable). For

"in situ" steam sterilisation, conventional steam condition for this purpose should be balanced across filter element with a

small flow orifice directed from outside to in. After steam sterilisation, the element should be allowed to flash dry before

the process gas is turned on. For maximum service life, it is recommended to check from time to time filter integrity. In

case testing equipment is not available, it is suggested to replace the filter element every six calendar months.

FILTER ELEMENT SPECIFICATION:

Filter grade

0.01

μ

Max. temperature

200 °C

Max. sterilising temperature

138 °C (as per BS3970, part 3, cycle A)

Initial pressure drop, clean and dry

150 mbar

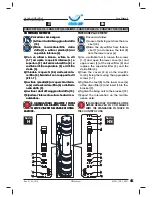

Change filter element

400 mbar

IMPORTANT NOTE:

-

Before replacing the filter element, make sure that the o-ring and the housing are clean and lubricated with

silicon compatible oil approved by F.D.A. (Food and Drug Administration)

-

Once differential pressure limits or working hours are reached, filter element must be replaced.

-

Only competent Personnel is allowed to install, perform maintenance or replace filter elements.

-

It’s forbidden to move or to replace any filter element from the filter housing under pressure.

INSTRUCTION MANUAL

MAN_CNC3_A001

EN

Summary of Contents for CLINIC 3/24

Page 77: ......