Page 10/48

© Geobrugg AG, CH-8590 Romanshorn, Switzerland

GBE-100A-R / 08

t

e

3

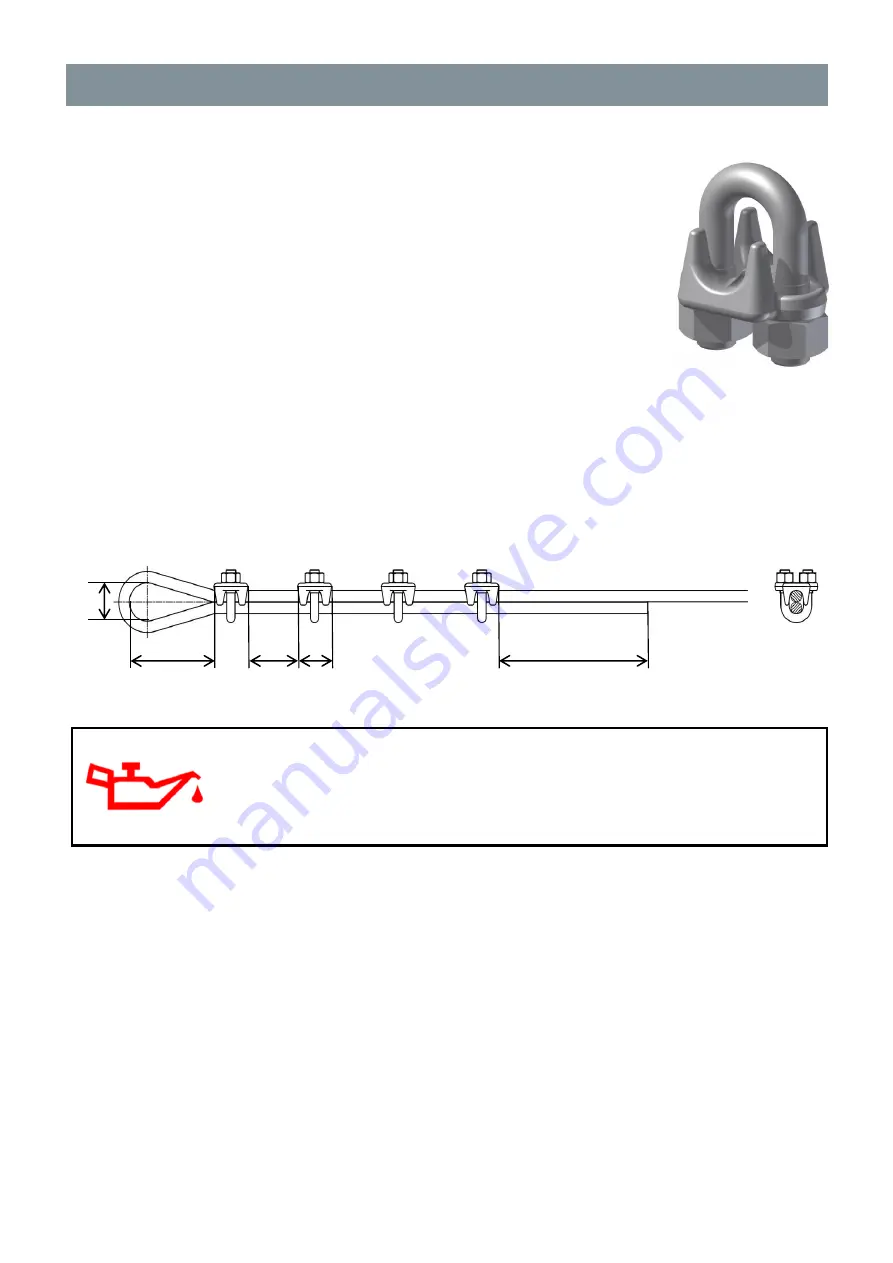

USING THE WIRE ROPE CLIPS

Instructions below apply to all wire rope clips according FF-C-450 type 1 class 1

(similar EN 13411-5 type 2) delivered by Geobrugg AG.

The distance

e

between the wire rope clips should be at least

1 x t

but not exceed

2

x t

, where

t

is the width of the clamping jaws. The loose rope end has to be

3 x e

at

a minimum. Geobrugg recommends looping up the remaining free section and fixing

it directly behind the last wire rope clip on the tightened rope.

If you are using a thimble in the loop structure, the first wire rope clip must be at-

tached directly next to the thimble. For loops without a thimble the length

h

between

the first wire rope clip and the point of load incidence must minimally be 15-time the

nominal diameter of the rope. In unloaded condition the length

h

of the loop should

be not less than the double of the loop width

h/2

.

The clamping brackets (U-brackets) must always be fitted to the unstressed end of the rope, the clamping jaws

(saddle) must always be fitted to the strained rope („never saddle a dead horse“).

During tightening the nuts have to be tensioned equally (alternately) until the required tightening torque is

reached.

The required tightening torques with lubrication apply to wire rope clips whose

bearing surfaces and the threads of the nuts have been greased with Panolin CL

60 multipurpose lubricant spray (or an equivalent lubricant).

FF-C-450 type 1 class 1

min. 3 x e

h/2

h

Summary of Contents for GBE-100A-R

Page 2: ...Page 2 48 Geobrugg AG CH 8590 Romanshorn Switzerland GBE 100A R 08...

Page 3: ...Page 3 48 Geobrugg AG CH 8590 Romanshorn Switzerland GBE 100A R 08...

Page 45: ...Page 45 48 Geobrugg AG CH 8590 Romanshorn Switzerland GBE 100A R 08...

Page 46: ...Page 46 48 Geobrugg AG CH 8590 Romanshorn Switzerland GBE 100A R 08...

Page 47: ...Page 47 48 Geobrugg AG CH 8590 Romanshorn Switzerland GBE 100A R 08...