Page 20/55

© Geobrugg Gruppe, CH-8590 Romanshorn, Switzerland

RXE-1000 / 17

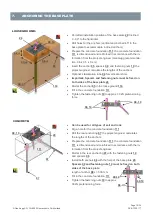

ROCK:

•

Remove rock around the base plate

29

at 0 - 30° to the hori-

zontal

•

Drill holes for the anchor

08

that are vertical to the base plate

29

into the rock

112

•

Mortar in the anchor

08

; the project engineer calculates the

lengths of the anchors

•

A thin leveling layer of mortar should ensure that the base

plate is in a stable position

•

Position the base plate

29

in the leveling layer of mortar

•

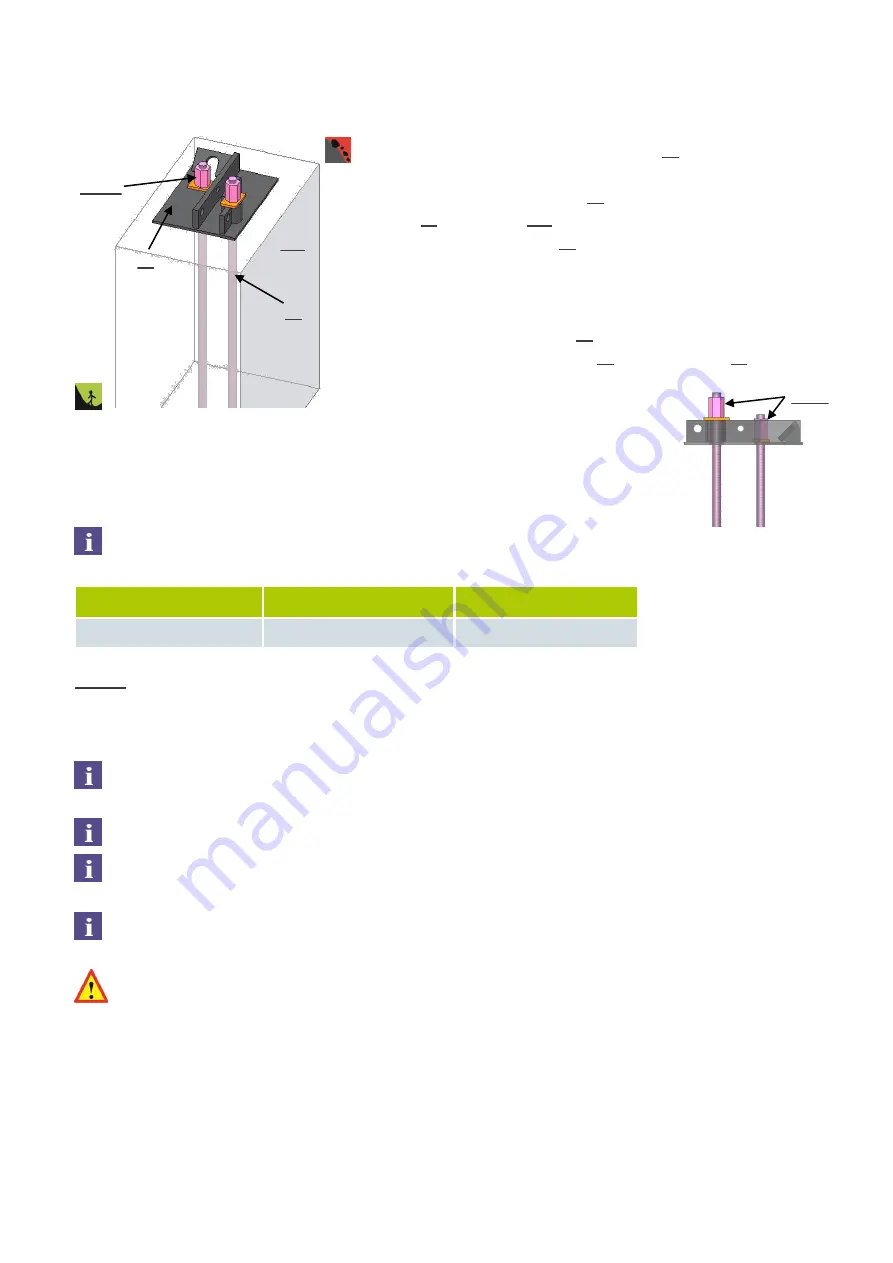

Tighten the fastening nuts

10

with the spacers

09

to approx.

30 kN pretensioning force after the mortar has fully hardened

Tightening torque of the fastening nut for an anchor pretensioning force of approx. 30 kN:

Swiss GEWI NG 25

Swiss GEWI NG 28

Tightening torque

300 Nm

400 Nm

Table 6

You must use mortar that is resistant to both frost and de-icing salt.

Reinforcement: 12 mm steel diameter, 150 mm apart

A mounting pattern can be supplied on request.

Please ensure the anchors have sufficient contact with the mortar, create a good bond, and that enough

of the surface contacts the surrounding material.

You can find more information about anchoring the base plate in the anchor data sheet.

The forces that may occur in the event of a rockfall event must not be underestimated. Civil engineering

and installation work must therefore be carried out by experts.

112

08

29

09, 10

09,10

Summary of Contents for RXE-1000

Page 2: ...Page 2 55 Geobrugg AG CH 8590 Romanshorn Switzerland RXE 1000 17 ...

Page 3: ...Page 3 55 Geobrugg AG CH 8590 Romanshorn Switzerland RXE 1000 17 ...

Page 52: ...Page 52 55 Geobrugg Gruppe CH 8590 Romanshorn Switzerland RXE 1000 17 ...

Page 53: ...Page 53 55 Geobrugg AG CH 8590 Romanshorn Switzerland RXE 1000 17 ...

Page 54: ...Page 54 55 Geobrugg Gruppe CH 8590 Romanshorn Switzerland RXE 1000 17 ...