25

Geokon Model

Gauge Type

Description

4000

3

Strain Gauge

4100

1

Strain Gauge

4200

3

Strain Gauge

4204

6

Strain Gauge

4202/421X

1

Strain Gauge

4300BX

1

BX Borehole Stressmeter

4300EX

5

EX Borehole Stressmeter

4300NX

1

NX Borehole Stressmeter

4400

1

Embedment Jointmeter

4420

1

Crackmeter

4450

1

Displacement Transducer

4500

1

Piezometer

4600/4651/4675

1

Settlement Systems

4700

1

Temperature Transducer

4800

1

Pressure Cell

4850

1

Low Pressure Piezometer

4900

1

Load Cell

4910/4911/4912

1

Load Bolts

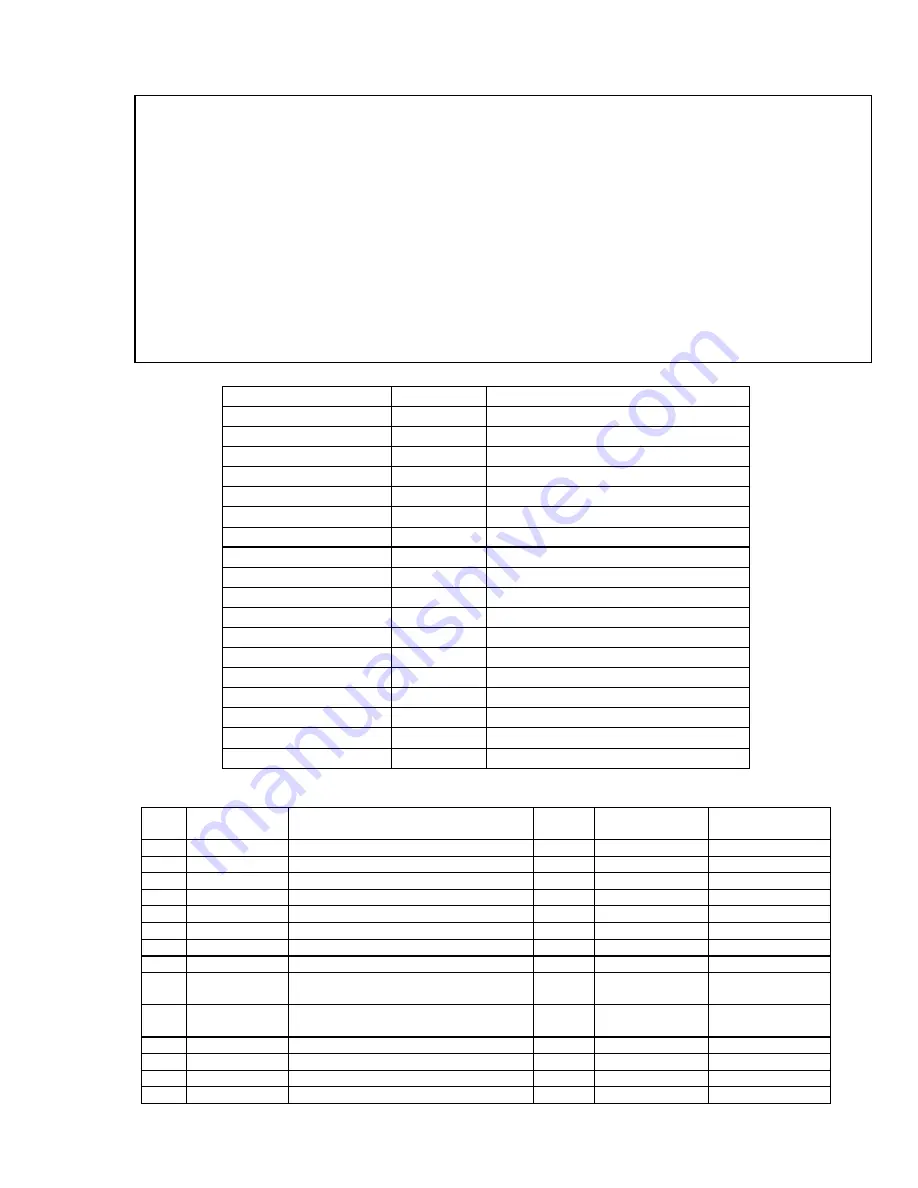

Table 2 - Vibrating Wire Gauge Types

Type Measurement

Type

Description

Output

Units

Linear Range

Polynomial Range

0

Vibrating Wire

Test frequency sweep, 400-4500 Hz

Digits

160 to 20250

0.160 to 20.250

1

Vibrating Wire

Middle frequency sweep, 1400-3500 Hz

Digits

1960 to 12250

1.960 to 12.250

2

Vibrating Wire

High frequency sweep, 2800-4500 Hz

Digits

7840 to 20250

7.840 to 20.250

3

Vibrating Wire Very low frequency sweep, 400-1200 Hz

Digits

160 to 1440

0.160 to 1.440

4

Vibrating Wire

Low frequency sweep, 1200-2800 Hz

Digits

1440 to 7840

1.440 to 7.840

5

Vibrating Wire Very high frequency sweep, 2500-4500 Hz Digits

6250 to 20250

6.250 to 20.250

6

Vibrating Wire

Low frequency sweep, 800-1600 Hz

Digits

640 to 2560

0.640 to 2.560

7-84

Not assigned

85

External

thermistor

Reads the thermistor encapsulated in the

Vibrating Wire instrument.

°C

-50 to +80

-50 to +80

86

Internal

thermistor

Reads the thermistor installed in the LC-2

Printed Circuit Board (PCB)

°C

-50 to +80

-50 to +80

87 Main battery: 12V

Reads the main 12V battery voltage

VDC

0 to 15

0 to 15

88-94

Not assigned

95 3V lithium battery

Reads the 3V lithium RTC battery

VDC

0 to 3.5

0 to 3.5

97 Main battery: 3V

Reads the main 3V battery voltage

VDC

0 to 7.5

0 to 3.5

Table 3 - Gauge Type Descriptions

NOTE: When using the Polynomial conversion method, the default reading units for a vibrating

wire instrument is the frequency squared multiplied by 10

-6

. For example, an instrument reading

3000Hz will output a value of “9.000” when A is entered as “0”, B is “1” and C is “0”. However,

typical calibration units for vibrating wire instruments are frequency squared multiplied by 10

-3

.

To adjust for this discrepancy between LC-2 expected units and calibration units

multiply the A

coefficient by 1,000,000 and the B coefficient by 1000. The A and B coefficients can be

found on the supplied calibration certificate.

The

C

coefficient should be calculated based on

an actual field reading.

The above multiplication is

only

necessary if the datalogger is being set

up via text commands (see Section 3.5 for an example setup using text commands)

AND

the

gage conversion is set for polynomial. When using LogView to setup the datalogger

configuration, the multiplication is performed by LogView. Refer to the appropriate sensor

manual for more information on how to calculate the

C

coefficient.