18

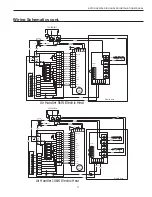

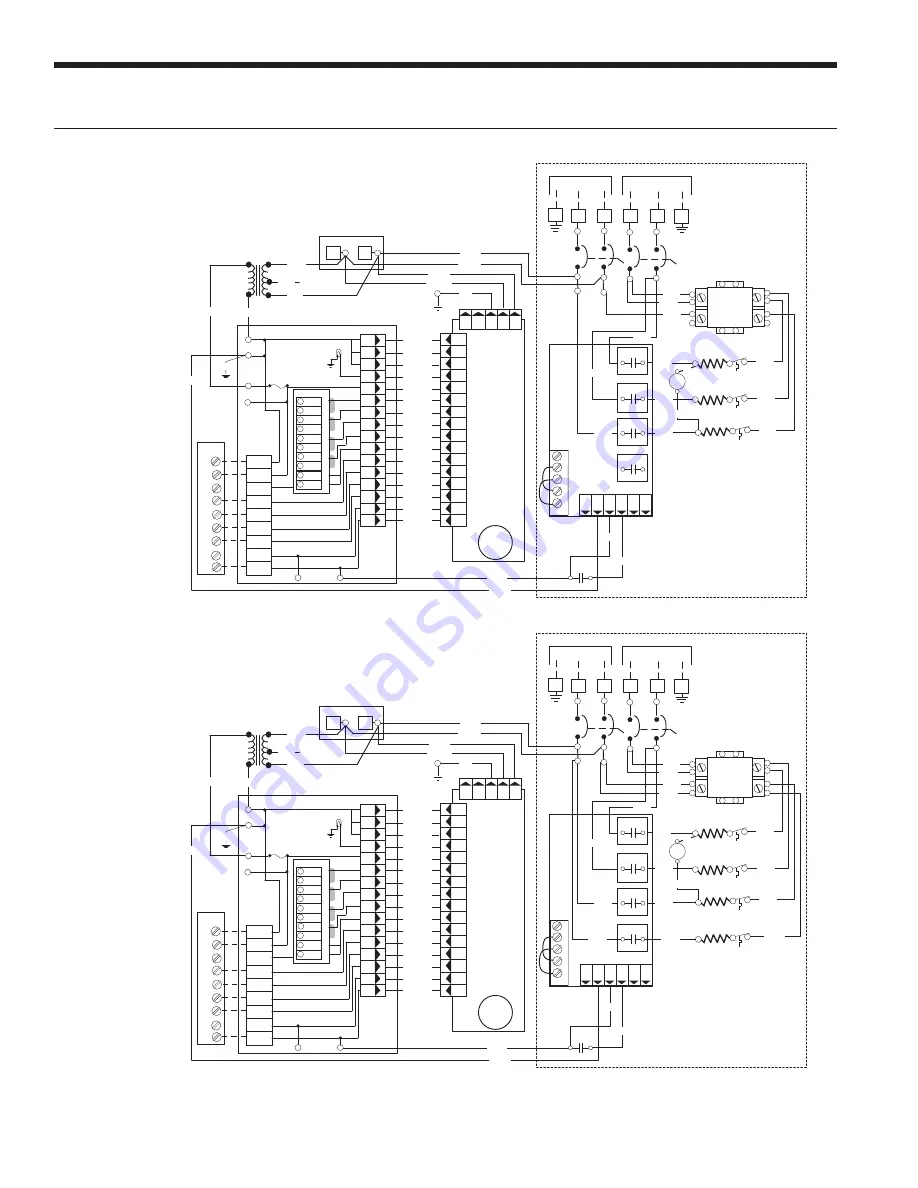

Wiring Schematics cont.

Air Handler w/ 20kW Electric Heat

Thermostat

R

C

Y1

O

W

Y2

Transformer

G

Grn

2

3

4

5

1

Blk/Wh

Yel

24V

208-230/60/1

G

L2

L1

PB

Orange

Brown

TDR

Grn(9)

L1

L2

BRK2

L1

L2

BRK1

Wht(8)

Grn(9)

P4

XFRM

SEC

C

R

Y1

Y2

On

SW1

1

2

3

4

5

6

7

8

9

10

O/B

G

W1

ODD

W2

C

R

LED

W1

W2

G

Circuit 2

208-230/60/1

Circuit 1

Black

Blue

Red

NOTE 1

Red (2)

Black(3)

Grn/Yel(1)

Electric Heat

Note 3

P3

ECM

Blower

Motor

On/Off

BK

RPM

C2

RPM grnd

C1

EM / W2

ADJUST

DELAY

COOL

Y /Y2

R

Y1

O

W / W1

HEAT

11

12

16

8

1

7

10

3

5

4

6

13

9

15

2

14

11

12

16

8

1

7

6

13

9

10

15

3

5

4

2

14

Note 4

Black (13)

Black (2)

Black (9)

Black (15)

Black (14)

Black (6)

Black (10)

Black (4)

Black (11)

Black (7)

Black (5)

Black (12)

Black (16)

Black (1)

Black (3)

Black (8)

EHC

Yel(17)

Blk(15)

Gry(13)

HE3

TS3

HE2

TS2

HE1

TS1

Gry(12)

Blk(14)

Yel(16)

EHC

Blu

Blu

Blu(11)

Wht(10)

Gry(24)

Blk(25)

Yel(26)

Blk(21)

Gry(20)

Yel(22)

P2

Gray

ER4

NO

NOTE 2

ER3

NO

ER2

NO

ER1

NO

C

1

2

3

4

C

1

2

3

4

P1

PNK(19)

Pnk(23)

Pnk(27)

HE4

TS4

Pnk(18)

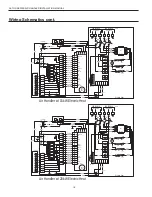

Air Handler w/ 15kW Electric Heat

Thermostat

R

C

Y1

O

W

Y2

Transformer

G

Grn

2

3

4

5

1

Blk/Wh

Yel

24V

208-230/60/1

G

L2

L1

PB

Orange

Brown

TDR

Grn(9)

L1

L2

BRK2

L1

L2

BRK1

Wht(8)

Grn(9)

P4

XFRM

SEC

C

R

Y1

Y2

On

SW1

1

2

3

4

5

6

7

8

9

10

O/B

G

W1

ODD

W2

C

R

LED

W1

W2

G

Circuit 2

208-230/60/1

Circuit 1

Black

Blue

Red

NOTE 1

Red (2)

Black(3)

Grn/Yel(1)

Electric Heat

Note 3

P3

ECM

Blower

Motor

On/Off

BK

RPM

C2

RPM grnd

C1

EM / W2

ADJUST

DELAY

COOL

Y /Y2

R

Y1

O

W / W1

HEAT

11

12

16

8

1

7

10

3

5

4

6

13

9

15

2

14

11

12

16

8

1

7

6

13

9

10

15

3

5

4

2

14

Note 4

Black (13)

Black (2)

Black (9)

Black (15)

Black (14)

Black (6)

Black (10)

Black (4)

Black (11)

Black (7)

Black (5)

Black (12)

Black (16)

Black (1)

Black (3)

Black (8)

EHC

Yel(17)

Blk(18)

Gry(13)

HE3

TS3

HE2

TS2

HE1

TS1

Gry(12)

Blk(14)

Yel(16)

EHC

Blu

Blu

Blu(11)

Wht(10)

Gry(24)

Blk(25)

Yel(26)

Blk(21)

Gry(20)

Yel(22)

P2

Gray

ER4

NO

NOTE 2

ER3

NO

ER2

NO

ER1

NO

C

1

2

3

4

C

1

2

3

4

P1

ASTON SERIES AIR HANDLER INSTALLATION MANUAL