33

Section 7: System Specifications

Applications

2" (5.8 cm) or larger recovery wells

Recovery Rate

.2 gallons (.750 ml) per cycle

Max. Operating Depth

180

’ (54.86 m)

Max. Pressure

100 PSIG (7 bar)

Max. Vacuum

20" (50 cm) Hg @ MSL (mean sea level)

Oil/Water Separation

Oleophilic/hydrophobic mesh screen

Power

Power Maximums

(AC Sipper) 87 to 240VAC, 2.7 to 1 Amp(s)

(Solar Sipper) 12-15VDC input @ up to 14.5 Amps

90 ~240 Watts continuous

Controller

Operating Temperature

0° to 40° C (32° to 104º F)

Storage Temperature Range

-29° to 66° C (-20º to 150º F)

Humidity

90% non-condensing (max)

Size

10" D x 18" T x 16

” W (25cm D x 46cm T x 40.5cm W)

Rating

NEMA 3R

Approximate Weight

35 lbs (16 kg) (single channel AC Sipper)

Approximate Weight

34 lbs (15 kg) (single channel Solar Sipper)

Approximate Weight

51 lbs (23 kg) (eight channel AC Sipper)

Approximate Weight

49 lbs (22 kg) (eight channel Solar Sipper)

Pump Assembly

Size:

23.5”L x 1.75” OD (60 cm L x 4.5 cm OD)

Weight:

4.5 lbs. (2 kg)

Materials:

303 and 304 SS, flexible rubber tubing, PVC, Brass

Skimmer Assembly

2” Model

4”Model

Effective travel range:

12” (3.7 m)

24” (7.3 m)

Size:

35.5” L x 1.75” OD

35.5” L x 3.75” OD

(90 cm L x 4.4 cm OD)

(90 cm L x 9.5 cm OD)

Weight:

1.75 lbs. (.8 kg)

2.25 lbs. (1 kg)

Operating Temperature:

0° to 40° C (32° to 104º F)

Storage Temperature:

-29° to 66° C (-20º to 150º F)

Materials:

304 SS, Polyethylene, PVC, Polypropylene, Brass

Tubing - Air:

.17" ID x .25" OD (4 mm ID x 6 mm OD)

Tubing - Discharge:

.375" ID x .5" OD (9.53 mm ID x 12.7 mm OD)

Power usage will vary depending on application.

Additional customizations and accessories could add more weight.

Summary of Contents for Solar Sipper

Page 1: ...Rev 10 12 2017 Part 16550176 Geotech Sipper Installation and Operation Manual...

Page 2: ...i...

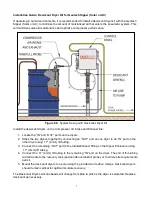

Page 16: ...13 Figure 2 5 Example of Tankfull Probe...

Page 23: ...20 Figure 3 1 Flowchart of User Interface Label...

Page 24: ...21 Figure 3 2 Example of Solar Sipper front panel...

Page 38: ...35 Section 8 System Schematics Figure 8 1 Solar Sipper Schematic...

Page 39: ...36 Figure 8 2 AC Sipper Schematic shown with optional Desiccant Dryers...

Page 40: ...37 Figure 8 3 8 Well Solar Sipper Internal Wiring Diagram...

Page 41: ...38 Figure 8 4 3 Well Solar Sipper Internal Wiring Diagram...

Page 45: ...42 Notes...