3

3.3 Installation of the baffleplate and

the dust collecting tray

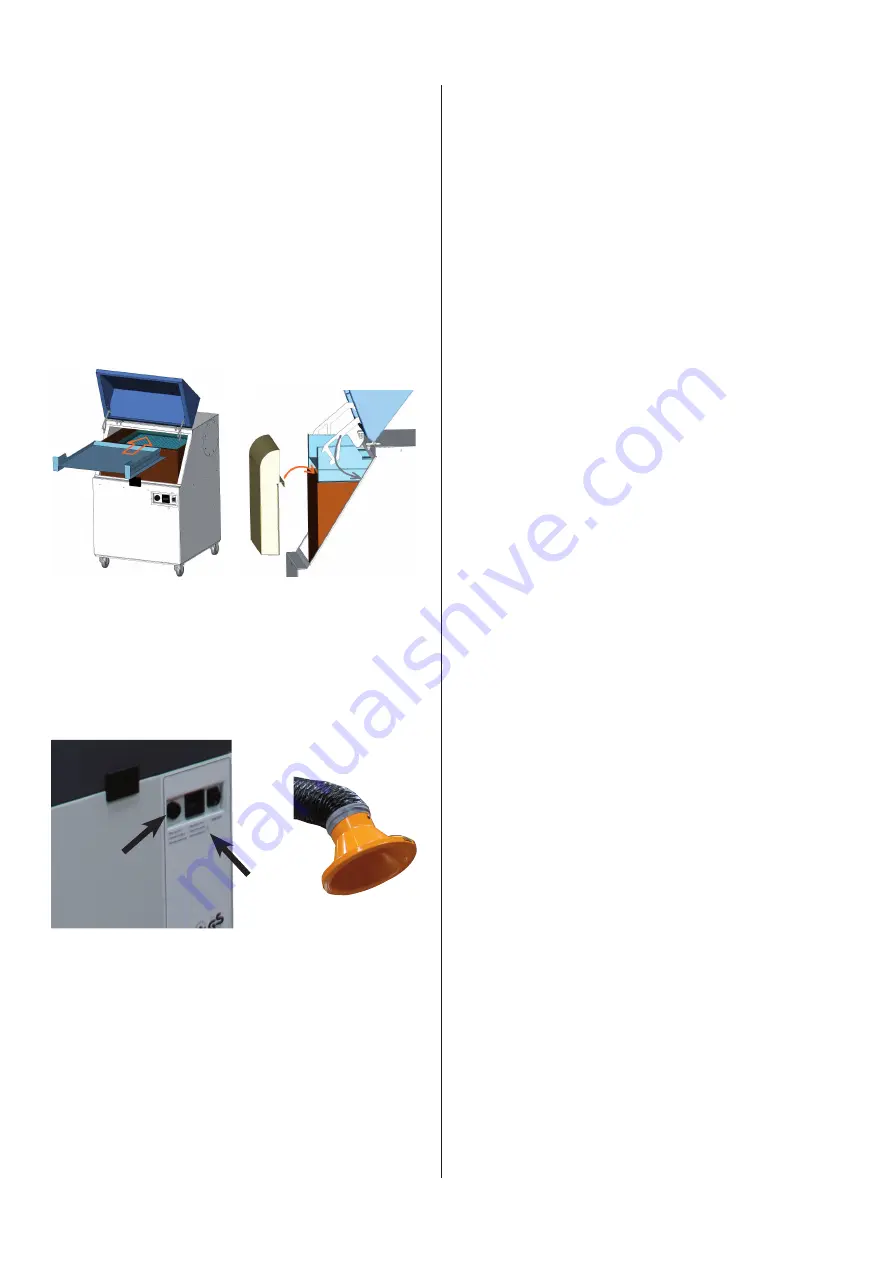

The baffle plate is inserted into the filter unit in the

shown mounting direction (illustration on the left).

The baffle plate lies on top of the particle filter and is

pushed till it is adjacent to the back of the housing.

The dust collecting tray is installed in front of the baffle

plate (illustration on the right). The bracket of the dust

collecting tray must be hung in the front frame of the

particle filter.

Finally the maintenance door is to be closed. The clam-

ping brackets on the baffle plate must thereby move

inside the housing.

BA_Staubvorabscheidung filtoo_150105_GB.doc

4

15.04.2014

3.3 Installation of the baffle plate and the dust collecting tray

The baffle plate is inserted into the filter unit in the shown mounting direction (illustration on the left).

The baffle plate lies on top of the particle filter and is pushed till it is adjacent to the back of the housing.

The dust collecting tray is installed in front of the baffle plate (illustration on the right). The bracket of the

dust collecting tray must be hung in the front frame of the particle filter.

Finally the maintenance door is to be closed. The clamping brackets on the baffle plate must thereby

move inside the housing.

3.4 Resetting of the pressure switch

for the filter control

The W3 is equipped with a filter control as a standard

feature which monitors the degree of saturation of the

filter element. Details on this can be found in the sepa-

rate operating manual of the W3. The hooter (A) begins

to sound when the filter control is triggered.

4 Maintenance

The dust collecting tray must be cleaned at regular in-

tervals. The intervals depend on the produced quantity

of dust and thus cannot be predetermined.

The negative pressure in the device changes when the

dust pre-separator is used and the filter control would

then indicate a filter alarm at an early stage. Therefore,

it is necessary to reset the pressure switch accordingly.

Proceed as follows:

.

The baffle plate and the collecting tray must be

installed and the maintenance door must be closed

as specified in chapter 3.3

.

Place a piece of cardbord in front og the hood, so if

covers app. 90% of the opening

(This, in combiation with new filter elements gene

-

rates a negative pressure comparable to saturated

filter elements with an open hood.)

.

Remove the masking cap (B). Here the alignment

of the pressure switch is located.

.

Now turn on the W3. Adjust the alarm value of the

pressure switch while the W3 is on.

Adjust the pressure switch by inserting a torx

screwdriver (T25 -T27) or flat-bladed screwdriver

(size 2 - 3.5) into the alignment aperture.

Turn the alignment clockwise till the signal hooter

stops. Now turn counter-clockwise till the signal

hooter restarts to sound. In this position the pres-

sure switch is optimally set.

.

Reattach the masking cap.

A

B