Summary of Contents for XLp

Page 5: ...5 XLp Installation Configuration June 2010 Overview Technical Specifications...

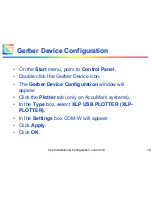

Page 17: ...17 XLp Installation Configuration June 2010 Software installation...

Page 41: ...41 XLp Installation Configuration June 2010 Components left side...

Page 42: ...42 XLp Installation Configuration June 2010 Components Operator Side...

Page 43: ...43 XLp Installation Configuration June 2010 Questions...