3

CAUTION – WARNING

1-WARNING!!

PLEASE TAKE NOTICE THAT the suggested maximum pressure and/or

temperature MUST NEVER BE EXCEEDED, as it may damage and/or cause ruptures and/

or leakages and/or even break the product, and present a potential hazard and danger to

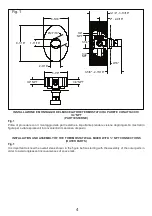

safety, health and/or property. Following are the technical data with respect to the installa-

tion of Gessi plumbing products.

►

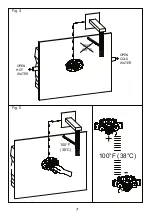

Working pressure should not be lower than 0,5 bar (7,25 psi) and not be higher than 5

bar (72 Psi). In case of higher working pressure use a pressure reducer valve.

►

Maximum test installation pressure: 8 bar (116 psi).

► Avoid major pressure differences between hot and cold water supply. Differences in

pressure, water with high mineral content, and soapy substances can corrode the inter-

nal and external parts of the hoses and slowly weaken the materials thereby causing

leakage.

► Maximum working temperature for Gessi products is 70 °C (158 °F).

2-WARNING!!

PLEASE TAKE NOTICE THAT the product should never be used as a tool,

hammer or for any purposes other than the one it has been designed for.

3-WARNING!!

PLEASE TAKE NOTICE THAT the product should always be installed and

tested by a professional plumber.

4-WARNING!!

PLEASE TAKE NOTICE THAT electric cables should never be attached to

the product as they may present a health and safety hazard.

5-WARNING!!

PLEASE TAKE NOTICE THAT heavy objects should never be placed on

or dropped on the product as they may damage the same and cause splinters, which may

present a health and safety hazard.

6-WARNING!!

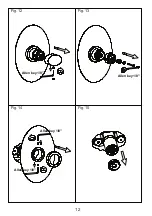

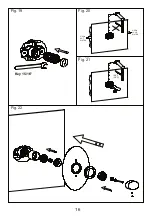

PLEASE TAKE NOTICE THAT the instructions manual should carefully read

before installation and the installation procedure provided therein must be properly followed

and complied with.

7-WARNING!!

PLEASE TAKE NOTICE THAT during installation the use of excessive force

should be avoided in order to prevent damage to the product and/or its components and

pieces. NEVER force a component or piece into another. NEVER force screws or over

tighten screws.